OLEDoS and Micro-OLED are advanced display technologies primarily used in microdisplays, especially for VR and AR applications. OLEDoS (OLED on Silicon) integrates OLED pixels on a silicon CMOS backplane, enabling extremely high pixel densities and efficiency. Micro-OLED is essentially a form of OLEDoS, known for its compact size, high resolution, and superior contrast compared to traditional OLED. Both offer unique advantages for near-eye displays, but subtle technological distinctions affect their performance and applications.

What Is OLEDoS and How Does It Work?

OLEDoS stands for OLED on Silicon, a microdisplay technology where organic light-emitting diode pixels are fabricated directly on a silicon wafer that contains CMOS circuitry. This integration allows for:

-

Extremely small pixel pitch (as low as 6.3 micrometers)

-

Ultra-high pixel density exceeding 4000 ppi

-

High emission efficiency due to a top-emission white OLED structure combined with color filters

-

Longer lifespan compared to traditional OLEDs

-

Compact form factor ideal for VR and AR headsets

The silicon backplane enables precise control of each pixel, resulting in superior image quality and power efficiency. This technology is particularly suited for applications requiring very high resolution in a small area, such as near-eye displays in virtual reality devices.

What Is Micro-OLED and How Is It Related to OLEDoS?

Micro-OLED is essentially a display technology that uses OLED pixels on a silicon substrate, making it synonymous or very closely related to OLEDoS. The term "Micro-OLED" has gained popularity especially with consumer products like Apple's Vision Pro headset, which uses micro-OLED displays to achieve 4K resolution per eye in a tiny footprint.

Key characteristics of Micro-OLED include:

-

Self-emissive pixels that can turn off individually for perfect blacks and high contrast

-

Very small pixel sizes allowing for extremely high resolution in compact displays

-

Fast refresh rates and wide color gamuts

-

Low power consumption depending on displayed content

Micro-OLED is effectively a commercial implementation of OLEDoS technology, emphasizing near-eye applications like AR/VR, electronic viewfinders, and head-up displays.

If you need High Contrast for near-eye viewing, Micro OLED is often the most direct path to razor-sharp UI and fine text.

How Do OLEDoS and Micro-OLED Compare to Traditional OLED?

| Feature | Traditional OLED | OLEDoS / Micro-OLED |

|---|---|---|

| Pixel Pitch | ~44 micrometers | As low as 6.3 micrometers |

| Pixel Density | Up to ~577 ppi | Over 4000 ppi |

| Backplane Material | Glass (LTPS or AMOLED) | Silicon CMOS wafer |

| Emission Structure | Bottom emission | Top emission with white OLED + CF |

| Lifetime | Moderate | Longer due to efficient structure |

| Typical Applications | TVs, smartphones, monitors | VR/AR headsets, microdisplays |

| Power Efficiency | Moderate | Higher due to precise pixel control |

OLEDoS/Micro-OLED's use of silicon backplanes enables far higher pixel densities and improved efficiency compared to traditional OLED panels, which use glass substrates and have larger pixels.

Why Are OLEDoS and Micro-OLED Ideal for VR and AR Applications?

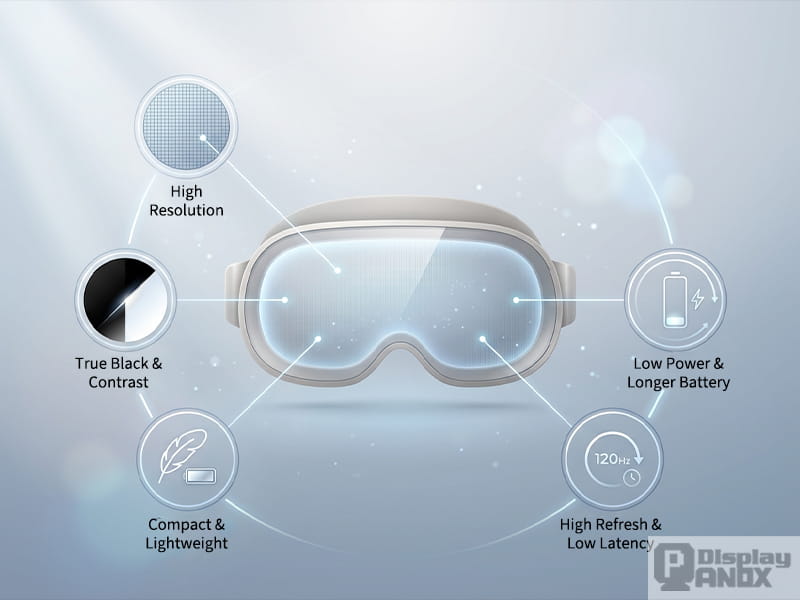

Both OLEDoS and Micro-OLED excel in near-eye display applications due to their:

-

Extremely high resolution in very small display areas, critical for immersive VR/AR experiences without visible pixels

-

High contrast and perfect blacks, enhancing image realism and reducing eye strain

-

Compact size and lightweight form factor, important for wearable comfort

-

Fast refresh rates that minimize motion blur and latency

-

Lower power consumption, extending battery life in portable devices

These advantages have made OLEDoS/Micro-OLED the go-to technology for cutting-edge headsets like the Apple Vision Pro and other mixed reality devices.

Which Industries Benefit Most from OLEDoS and Micro-OLED Technology?

Industries leveraging these microdisplay technologies include:

-

Virtual Reality (VR) and Augmented Reality (AR): For immersive headsets with ultra-high resolution

-

Wearable Devices: Smart glasses and heads-up displays requiring compact, high-quality screens

-

Military and Aviation: Helmet-mounted displays and HUDs with critical visual fidelity

-

Medical Imaging: Devices needing precise, high-contrast microdisplays

-

Consumer Electronics: Electronic viewfinders in cameras and next-gen smart devices

Panox Display, a leading supplier and OEM manufacturer, specializes in providing both OLEDoS and Micro-OLED solutions tailored for these demanding sectors.

How Does Panox Display Support OLEDoS and Micro-OLED Innovations?

Panox Display offers comprehensive services including:

-

Custom and standard OLED and Micro-OLED panels sourced from top manufacturers

-

Integration of controller boards, PCBs, and touch panels to deliver turnkey display solutions

-

Support for startups and SMEs with flexible MOQs and cost-effective sourcing

-

Expertise in microdisplay applications for VR, AR, automotive, and industrial markets

By leveraging Panox Display’s expertise, clients gain access to cutting-edge OLEDoS and Micro-OLED technologies optimized for their specific needs.

Explore our Micro OLED options for near-eye display projects.

What Are the Main Challenges Facing OLEDoS and Micro-OLED Technologies?

Despite their advantages, these technologies face challenges such as:

-

High manufacturing complexity and cost due to silicon backplane integration

-

Limited production capacity compared to traditional OLEDs

-

Potential lifetime limitations related to organic materials, though improved in OLEDoS structures

-

Competition from emerging microLED displays, which offer higher brightness and durability but are not yet widely commercialized

Panox Display actively works to overcome these hurdles by collaborating with leading panel makers and advancing custom solutions.

Can OLEDoS and Micro-OLED Replace Other Display Technologies?

While OLEDoS and Micro-OLED are currently the state-of-the-art for microdisplays, especially near-eye applications, they are unlikely to fully replace traditional OLED or LCD in larger formats anytime soon. Their niche lies in:

-

Ultra-high resolution small displays

-

Applications demanding perfect blacks and high contrast in compact sizes

For larger TVs and monitors, traditional OLED and emerging technologies like QD-OLED and MicroLED remain dominant.

What Future Developments Are Expected in OLEDoS and Micro-OLED?

The future promises:

-

Further pixel density improvements beyond 4000 ppi

-

Enhanced lifetime and efficiency through materials innovation

-

Broader adoption in consumer AR/VR devices as costs decrease

-

Integration with sensors and other silicon-based components for smarter displays

-

Potential hybrid solutions combining Micro-OLED with microLED for optimal performance

Panox Display is at the forefront of these advancements, helping clients stay competitive in the evolving display landscape.

Panox Display Expert Views

"OLEDoS and Micro-OLED represent a paradigm shift in microdisplay technology, enabling unprecedented pixel densities and image quality in compact form factors. At Panox Display, we see these technologies as essential enablers for the next generation of immersive AR and VR experiences. Our commitment is to provide flexible, high-quality OLED and Micro-OLED solutions that empower innovators worldwide to push the boundaries of visual technology." — Senior Display Engineer, Panox Display

How Does OLEDoS Compare to MicroLED and Other Emerging Microdisplay Technologies?

| Technology | Pixel Size | Brightness | Power Efficiency | Lifetime | Typical Use Cases |

|---|---|---|---|---|---|

| OLEDoS/Micro-OLED | ~6.3 µm | Moderate | High | Moderate to High | VR/AR headsets, microdisplays |

| MicroLED | Variable (larger) | Very High | Very High | Very High | Smartphones, smartwatches, future TVs |

| Traditional OLED | ~44 µm | Moderate | Moderate | Moderate | TVs, smartphones |

MicroLED offers higher brightness and longer lifetime but is currently more complex and costly to manufacture at microdisplay scale. OLEDoS/Micro-OLED remains the preferred technology for ultra-high resolution near-eye displays today.

What Are the Cost Implications of Choosing OLEDoS vs Micro-OLED?

Since Micro-OLED is effectively a commercial term for OLEDoS technology, cost differences are minimal and depend mostly on panel size, resolution, and supplier. Both tend to be more expensive than traditional OLED due to:

-

Silicon wafer backplane fabrication

-

Complex manufacturing processes

-

Smaller production scales

Panox Display helps mitigate these costs by offering flexible MOQ and custom solutions, making advanced microdisplays more accessible.

Conclusion

OLEDoS and Micro-OLED are cutting-edge microdisplay technologies that deliver ultra-high resolution, excellent contrast, and compact form factors ideal for VR, AR, and other near-eye applications. While closely related and often interchangeable terms, OLEDoS emphasizes the silicon backplane integration, and Micro-OLED highlights the commercial display implementation. Despite challenges in cost and production complexity, these technologies represent the future of immersive display experiences. Panox Display stands out as a trusted partner supplying high-quality OLEDoS and Micro-OLED panels and solutions, empowering innovation across industries.

Learn more: Why You Should Go for Micro-OLED: The Next Great Leap in VR & Professional Visuals

Frequently Asked Questions (FAQs)

Q1: Is Micro-OLED the same as OLEDoS?

A1: Yes, Micro-OLED generally refers to OLED-on-silicon (OLEDoS) technology, where OLED pixels are built on a silicon CMOS backplane for high-resolution microdisplays.

Q2: What advantages do OLEDoS/Micro-OLED displays have over traditional OLED?

A2: They offer much higher pixel density, better power efficiency, longer lifespan, and are more suitable for compact, near-eye display applications.

Q3: Can OLEDoS displays be used in smartphones?

A3: Currently, OLEDoS/Micro-OLED is mainly used in VR/AR headsets and microdisplays rather than smartphones, which often use microLED or traditional OLED.

Q4: How does Panox Display contribute to OLEDoS and Micro-OLED technology?

A4: Panox Display provides OEM manufacturing, custom solutions, and sourcing of high-quality OLEDoS and Micro-OLED panels, supporting various industries globally.

Q5: Will MicroLED replace OLEDoS in the future?

A5: MicroLED may offer advantages in brightness and durability but is not yet commercially viable for microdisplays; OLEDoS/Micro-OLED remains the leading technology for now.

| Panel model | Interface | Type | Size (inch) | Resolution | P.S |

| S032WEM01 | MIPI/RGB | Micro OLED | 0.32 | 800x600 | |

| PMOF039XGAM | RGB | Micro OLED | 0.39 | 1024x768 | Full Color/Monochrome |

| BO039M1920M | MIPI | Micro OLED | 0.39 | 1920x1080 | Highest PPI =5644 |

| EP047M800T | TTL | LCOS | 0.47 | 800x600 | |

| BO049FHPMO | SPI,MIPI | Micro OLED | 0.49 | 1920x1080 | |

| S050M1600M | MIPI | Micro OLED | 0.5 | 1600x1200 | |

| ECX331DB-6 | Mini LVDS | Micro OLED | 0.5 | 1024x768 | |

| S060LDM01 | MIPI | Micro OLED | 0.6 | 1920x1080 | |

| ECX335AF | Mini LVDS | Micro OLED | 0.71 | 1920x1080 | 200 nits brightness version |

| ECX335B | Mini LVDS | Micro OLED | 0.71 | 1920x1080 | 500 nits brightness version |

| ECX335SN | Mini LVDS | Micro OLED | 0.71 | 1920x1080 | 3000 nits brightness version |

| BO071M1920M | MIPI | Micro OLED | 0.71 | 1920x1080 | |

| S072WCM04 | MIPI | Micro OLED | 0.72 | 1920x1080 | |

| S103WAM01 | MIPI | Micro OLED | 1.03 | 2560x2560 |