Engineers and product designers frequently encounter a critical decision when specifying displays for challenging lighting environments: selecting the right surface treatment. While anti glare and anti reflection technologies both address visibility issues caused by ambient light, they function through fundamentally different mechanisms and deliver distinct performance characteristics. Understanding these differences is decisive for selecting the optimal solution for your particular application requirements.

Related: Looking for a readable-under-sun display panel?

The Physics of Visibility and Light

To understand the value of these coatings, one must first look at why readability suffers in bright conditions. Light reflection occurs when electromagnetic radiation encounters the boundary between two materials with different refractive indices, such as air and glass. For standard glass surfaces, approximately 4-5% of incident light reflects at each interface. In a typical display stack with protective glass, this creates multiple reflection points—from the air-to-glass surface, the glass-to-air gap, and the air-to-display surface.

These reflections add unwanted brightness to both the dark and bright areas of the content, which significantly reduces the effective contrast ratios (ECR). For example, in outdoor environments with high ambient illumination (10,000 candelas), even a standard 4.5% reflection rate can crash a display’s contrast from 400:1 down to approximately 4-5:1, which is barely readable.

How Anti-Glare (AG) Coatings Work

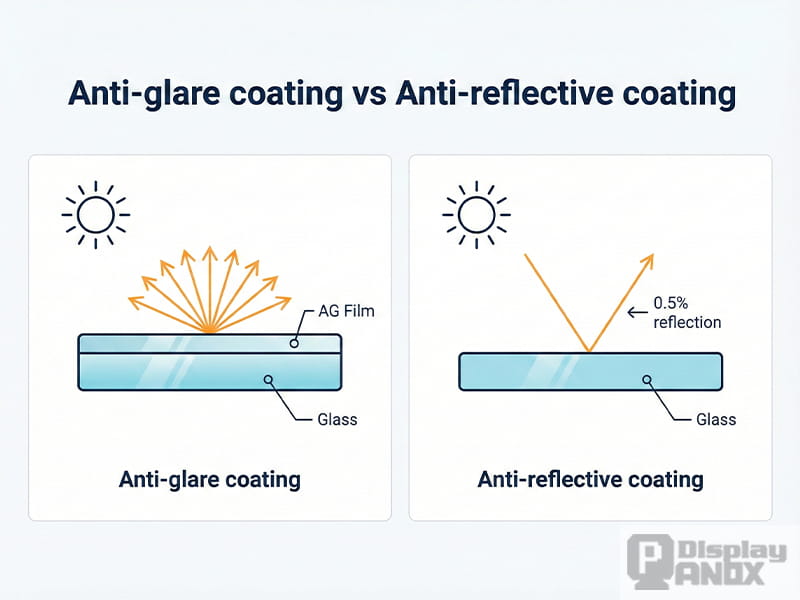

Anti glare and anti reflection solutions take different approaches to this problem. Anti-glare coatings function by dealing with the reflection after it has happened. They feature a microscopic texturing or roughness on the glass surface, created through chemical etching or particle deposition.

This texture works by scattering reflected light in multiple directions rather than allowing it to bounce back directly. By breaking up specular (mirror-like) reflections into diffuse patterns, the coating makes reflections less perceptible to viewers positioned directly in front of the screen. The human eye perceives this scattered light as less intense because the same amount of light energy is spread across wider angles.

Pros and Cons of AG:

-

Cost and Production: AG is cost-effective, typically costing 30-50% less than equivalent anti reflection solutions. The manufacturing processes are well-established, allowing for shorter lead times and application to various substrates.

-

Performance: It provides reliable glare reduction for indoor and moderate outdoor use.

-

Trade-offs: The diffusion mechanism that scatters external light also affects light emanating from the display. This causes image softening, reduced apparent resolution, and decreased color saturation. Furthermore, the textured surface tends to attract contaminants, making cleaning more difficult—a concern for medical or food service environments.

The Science Behind Anti-Reflection (AR) Coatings

In the anti glare anti reflection comparison, AR coatings offer a more sophisticated optical approach. Instead of scattering light, anti reflection coatings use thin-film interference principles to minimize the quantity of light reflected in the first place.

Manufacturers deposit multi-layer dielectric films with precisely controlled thicknesses and refractive indices onto the glass. When light hits the coating-air and coating-glass interfaces, the reflections cancel each other out at specific wavelengths through destructive interference. Advanced AR coatings can reduce reflectance from 8% (combined glass surfaces) to less than 0.5%, whle maintaining over 99% light transmission. This represents a genuine reduction in reflected light energy, rather than just a redistribution.

Pros and Cons of AR:

-

Image Fidelity: AR coatings improve effective contrast ratios without compromising image quality. The smooth surface maintains the display’s original resolution and color characteristics.

-

Maintenance: Unlike textured AG surfaces, AR coatings are smooth and easier to clean.

-

Challenges: The primary drawback is cost and complexity; the vacuum deposition process requires sophisticated equipment. Additionally, while AR improves visibility, it can be susceptible to abrasion damage, though modern hard coatings mitigate this effectively.

Strategic Recommendations for Your Project

When choosing between anti glare and anti reflection, the decision ultimately depends on balancing performance requirements against budget constraints.

When to Choose Anti-Glare:

AG treatments are best for volume applications where moderate image degradation is acceptable in exchange for cost savings. They are widely used in point-of-sale terminals, outdoor signage, and consumer electronics. However, for high-resolution displays above 300 PPI, AG structures may cause visible interference, making untreated or AR surfaces a better choice30.

When to Choose Anti-Reflection:

For applications prioritizing image fidelity, anti reflection coatings are superior. They are the standard for medical displays, high-resolution industrial monitors, and military systems where maximum readability is non-negotiable. AR is also ideal for EV chargers and automotive dashboards exposed to direct sunlight. When combined with optical bonding to eliminate air gaps, AR coatings can achieve effective contrast ratios above 15:1 even in bright outdoor settings.

In scenarios where display readability directly impacts safety or operational efficiency, the premium for anti reflection coatings proves worthwhile. Conversely, for general-purpose use in controlled lighting, anti-glare provides adequate performance at a lower price point.

If you’re looking for more anti-reflection display solutions, we can share a broader product list to match your needs.