![]()

In the rapidly evolving world of display technology, comparing datasheets can often be misleading. Engineers and procurement managers frequently notice a disparity when evaluating specifications: on paper, QLED (Quantum Dot LED) panels often boast higher peak brightness numbers and longer lifespan ratings than Micro OLED units. This leads to a common question: Why are the specs on Micro OLED lower than QLED?

The answer lies in the fundamental purpose of the hardware. The comparison is not a matter of one technology being superior to the other in a vacuum; rather, it is a distinction between "macro" power and "micro" precision. While QLED is designed to illuminate living rooms, Micro OLED is engineered to fool the human eye in virtual environments. To understand the true value of Micro OLED, we must look beyond the raw numbers and examine the architectural differences in the qled vs oled debate.

The Architecture Gap: Silicon vs. Glass substrates

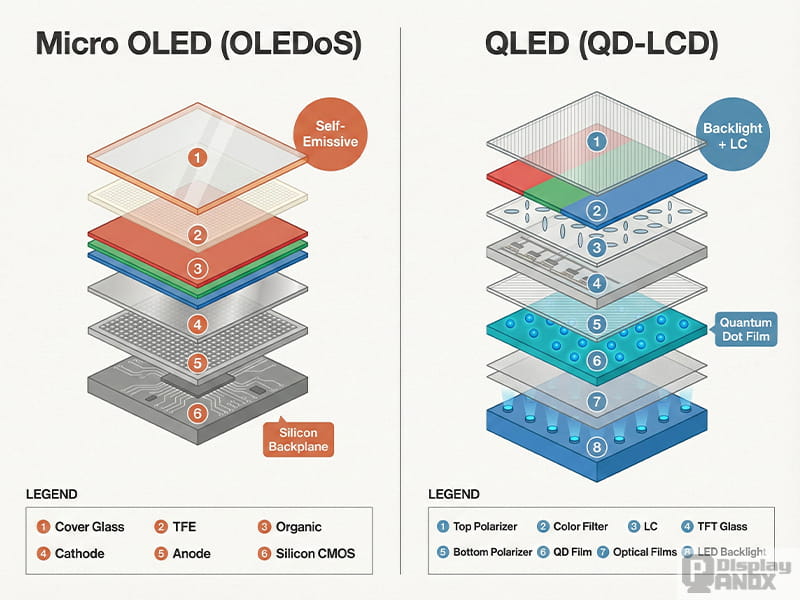

To understand the specifications, one must first understand the manufacturing process. QLED is arguably the pinnacle of traditional LCD technology. It utilizes a transmissive structure where a backlight (usually Blue LED) passes through a Quantum Dot enhancement film and then through a liquid crystal layer. This allows for massive photon throughput, resulting in the high brightness figures seen on TV datasheets.

Micro OLED, also known as OLEDoS (OLED on Silicon), is a different beast entirely. It is not built on a glass substrate like a TV or smartphone screen; it is built on a silicon wafer, similar to a computer processor. This allows for the integration of driving circuitry directly behind the pixels. While this architecture limits the total surface area and heat dissipation capabilities—resulting in "lower" brightness ceilings compared to large-panel QLEDs—it unlocks a level of density and speed that QLED simply cannot physically achieve.

Decoding the "Lower" Specs: Context is King

When a datasheet shows a QLED panel hitting 4,000 nits and a Micro OLED panel targeting 3,000 nits, the numbers do not tell the full story. The application environment dictates the necessity of these specs.

1. Brightness vs. Perceived Luminance

QLED displays are typically viewed from a distance of several feet in rooms filled with ambient light. They require massive light output (nits) to combat reflections and sunlight. In contrast, Micro OLEDs are primarily designed for Near-Eye Displays (NEDs), such as Electronic Viewfinders (EVFs), VR headsets, and AR glasses.

In a Near-Eye optical system, the display is coupled with lenses that sit millimeters from the pupil. While the raw brightness output might seem lower than a flagship TV, the perceived brightness is intense. Furthermore, in VR applications, absolute black levels are more critical than absolute brightness. Because Micro OLED is self-emissive, it achieves perfect black (0 nits), creating an "infinite" contrast ratio. A QLED, relying on a backlight, will always have some light leakage (blooming), which destroys immersion in a headset regardless of how bright the peak highlights are.

If your project needs strong visibility under ambient light, check our High Brightness display selections here.

2. Lifespan and Organic Materials

It is true that inorganic QLED panels have a longer theoretical lifespan than organic OLED materials, particularly under high thermal stress. However, Micro OLED manufacturers have mitigated this through advanced tandem structures and heat-dissipating silicon backplanes. For the specific use cases of Micro OLED—such as industrial thermal imagers, surgical scopes, or consumer VR—the operational lifespan is more than sufficient for the product's lifecycle, offering a trade-off that prioritizes image quality over 24/7 signage durability.

The "Hidden" Specs: Where Micro OLED Dominates

If Micro OLED "loses" on raw brightness output, it wins decisively on the metrics that matter most for immersion and optical precision. These are the specifications that often define the success of a high-end optical product.

Pixel Density (PPI) and PPD

This is the single most important metric for any device worn on the head. A standard 4K QLED monitor might have a pixel density of 140–160 PPI (Pixels Per Inch). If you were to place a QLED panel under a magnifying lens for VR, you would see a distinct "Screen Door Effect"—the black grid between pixels.

Micro OLEDs routinely achieve 3,000 to 6,000+ PPI. Because the pixels are micron-sized and deposited on silicon, they are virtually invisible to the naked eye, even under high magnification. In the Micro OLED vs QLED comparison, this density is the differentiator between a pixelated image and a photorealistic reality. For applications requiring high "Pixels Per Degree" (PPD), Micro OLED is currently the only viable commercial solution.

Response Time and Latency

In Virtual Reality and tactical optics, latency causes motion sickness. QLED panels, limited by the physical rotation speed of liquid crystals, typically offer response times between 1ms and 5ms. While fast enough for gaming monitors, this introduces "smearing" in rapid head-tracking scenarios.

Micro OLED pixels switch states in microseconds (<0.01ms). This near-instantaneous response time allows for techniques like low-persistence display modes, which eliminate motion blur and ensure that the visual data matches the user's vestibular system, preventing nausea in VR environments.

Learn more: Why You Should Go for Micro-OLED: The Next Great Leap in VR & Professional Visuals

Conclusion: Choosing Precision over Power

The question of "Why are specs on Micro OLED lower than QLED?" is ultimately a misunderstanding of the metrics. QLED specs are higher in categories regarding raw output and scale (size, brightness, volume). However, Micro OLED specs are vastly superior in categories regarding precision (PPI, contrast, response time).

For television manufacturers, QLED remains a robust choice. But for engineers developing the next generation of spatial computing, thermal imaging, and wearable displays, the "lower" power specs of Micro OLED are a necessary trade-off to achieve the optical perfection required by the human eye. When clarity, contrast, and compact form factor are paramount, Micro OLED is not just a competitive alternative; it is the industry standard.

Ready to spec a near-eye microdisplay? Explore our Micro OLED products here.