When we evaluate the quality of a foldable device, we often get distracted by resolution, brightness, or color gamut. However, the reality of engineering a foldable display is far more complex. Flexible OLED isn’t a panel spec game; it is a stack system game.

The success of a foldable device—whether it survives 200,000 folds or feels premium to the touch—is rarely determined by the OLED pixels alone. Instead, it is defined by how well a composite structure of disparate materials handles the physics of bending. If you want to understand the longevity and user experience of a foldable device, you must look beyond the screen and analyze the entire stack.

Browse our complete catalog of to Flexible OLED modules find the perfect fit for your design.

Defining the Stack: It’s All Connected

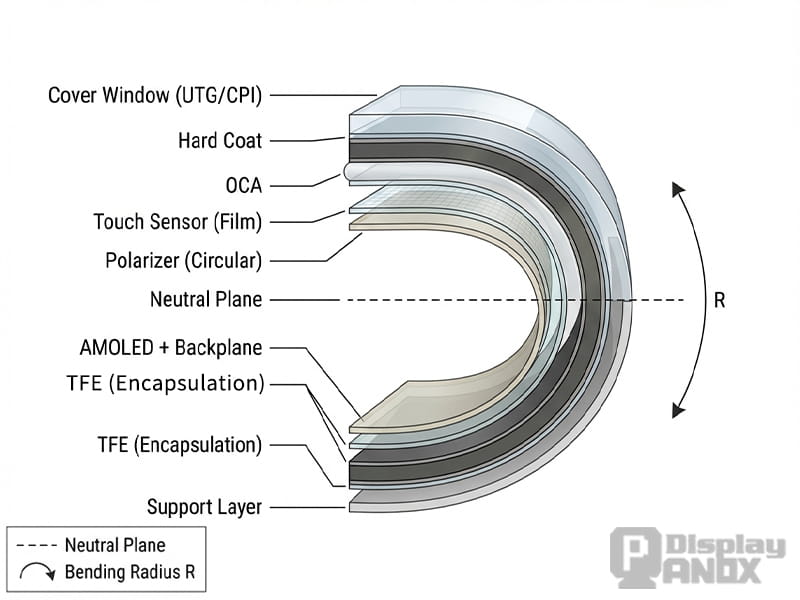

To understand the engineering challenge, we must first define the scope of the "Stack." In the context of flexible displays, the stack is a tightly integrated sandwich comprising the Cover Window, Optically Clear Adhesive (OCA), Touch Sensors/Films, and the OLED Module itself.

These layers are not independent variables. According to materials science principles highlighted in journals like Nature, these layers interact mechanically. A change in the thickness of the cover window alters the stress placed on the underlying OLED panel. A change in the modulus (stiffness) of the adhesive changes how the device resists buckling. These layers function as a single mechanical system, and they collectively determine the final tactile feel, optical clarity, and mechanical lifespan of the product.

The Cover Window: Where Users "Touch the Truth"

The top layer—the Cover Window—is the most tangible differentiator in the foldable market. It represents the immediate interface between the user and the technology. Currently, the industry battle is primarily between Ultra-Thin Glass (UTG) and Colorless Polyimide (CPI).

While CPI offers excellent flexibility and lower manufacturing costs, market trends tracked by research firms like Omdia indicate a distinct shift toward UTG for flagship devices. The reason is tactile. Users associate the cold, smooth, and rigid feel of glass with premium quality. Furthermore, scratch resistance is a critical performance metric. While CPI is inherently shatter-resistant, it lacks the surface hardness of glass, often leading to distinct "plastic-like" depressions or scratches over time.

UTG aims to provide the hardness of glass while maintaining the flexibility required for a tight bending radius. However, integrating UTG requires precise stress management. If the stack design is poor, the high modulus of glass can transfer excessive stress to the delicate OLED layers below.

View Panox Display’s Flexible OLED lineup to compare options and select the bet.st match for your projec

OCA: Not Just Glue, But a Mechanical Buffer

Perhaps the most underestimated component in the flexible stack is the Optically Clear Adhesive (OCA). It is a mistake to view OCA simply as a bonding agent. In a foldable stack, OCA functions as both an optical component and a mechanical shock absorber.

Leading adhesive manufacturers, such as 3M, emphasize that the viscoelastic properties of OCA are critical for folding performance. The adhesive must be soft enough to allow the layers to slide over each other during folding (relieving shear stress) but elastic enough to recover instantly when the device is unfolded (preventing creeping or rippling).

This layer is instrumental in managing the Neutral Plane—the theoretical axis within the stack where there is zero tension or compression. By optimizing the thickness and position of the OCA, engineers can shift the Neutral Plane to protect the most fragile components, such as the thin-film encapsulation (TFE) or the conductive traces. If the OCA is too thin or lacks the correct stress relaxation properties, the risk of delamination or panel buckling increases significantly.

Reliability: Beyond the "Fold Count"

Marketing materials often boast about a device surviving 200,000 or 400,000 folds. However, reliability is not a single number; it is a complex equation of stress distribution.

Scientific studies on flexible electronics suggest that mechanical failure is rarely about a simple fatigue cycle. Instead, failure often stems from how stress accumulates in specific layers under varying conditions. Reliability is determined by how stress is distributed across the stack, not just how many times the hinge opens.

For example, the bending radius is a critical factor. As the radius decreases (making the device thinner when folded), the strain on the stack increases exponentially. Furthermore, environmental factors like heat and humidity can alter the chemical properties of the OCA and films, changing their stiffness and potentially shifting the Neutral Plane into a danger zone. Therefore, a robust stack design must account for dynamic bending under various environmental conditions, not just a static folding test in a controlled lab.

Conclusion: The Stack Is the Product

In the rapidly evolving world of flexible electronics, the display panel is no longer the sole definition of the product—it is merely the foundation. The true engineering feat lies in the stack integration.

Achieving a foldable device that is both durable and premium requires a shift in perspective: from sourcing components to architecting a system. The interaction between the Cover Window’s rigidity, the OCA’s viscoelasticity, and the OLED’s fragility creates a complex mechanical ecosystem. A failure in one layer inevitably compromises the others, regardless of the individual raw specifications.

Ultimately, high specifications might sell the first device, but stack harmony ensures the longevity that builds brand reputation. As the industry matures, the leaders will not be those who simply buy the brightest panels, but those who master the physics of the stack.

Explore Panox Display’s Flexible OLED modules to find the right fit for your design requirements.

Learn more:Flexible OLED Isn't About Bending — It's About Design Freedom

|