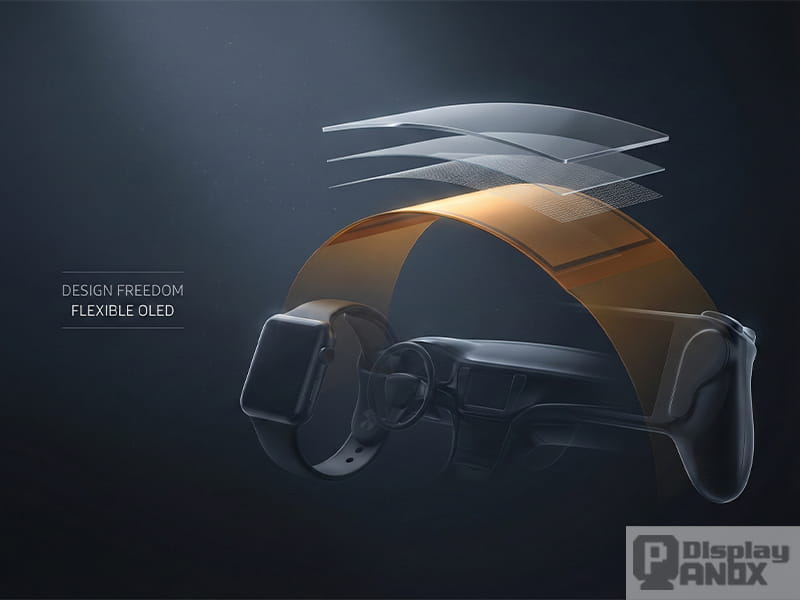

When the industry discusses Flexible OLED, the conversation is almost exclusively dominated by foldable smartphones and rollable TV prototypes. While these dynamic applications make for exciting trade show demonstrations, they obscure the true industrial value of the technology. For the majority of product designers, engineers, and product managers, the revolution isn't about the ability to fold a screen day-to-day. The revolution is static design freedom.

We need to downgrade the "bendable demo" from the protagonist role to a supporting character. The primary value of flexible OLED technology—specifically using polyimide substrates instead of rigid glass—is that it allows a product to reclaim its form. It enables devices to be thinner, lighter, and shaped to fit the human body or environment, rather than forcing the environment to fit a flat rectangle.

The bend is not the feature. The form factor is.

Browse our complete catalog of Flexible OLED modules to find the perfect fit for your design.

Defining "Design Freedom": Where Flexibility Meets Function

When we remove the constraint of a brittle glass substrate, we do not just gain a "bendy screen"; we gain a new toolkit for spatial efficiency and aesthetic continuity. Flexible OLED unlocks four specific dimensions of design freedom that rigid panels simply cannot accommodate.

A. Space Efficiency: Packaging Wins Before Pixels Do

In modern electronics, internal volume is the most expensive real estate. Rigid displays dictate a specific thickness and a required bezel width to house driver ICs (Chip-on-Glass). Flexible OLEDs rewrite this rule through Chip-on-Plastic (COP) technology. By bending the substrate behind the active area, manufacturers can eliminate the "chin" of a device, creating a symmetrical front face. Furthermore, the absence of a backlight unit and the use of ultra-thin encapsulation layers mean the display stack itself is significantly thinner. This allows engineers to increase battery size, improve thermal management, or simply slim down the device profile without sacrificing visual performance.

B. Surface Continuity: The Death of the "Screen + Bezel" Era

Traditionally, a device consists of a housing and a separate, flat window for the display. Flexible OLED allows for surface continuity, where the display follows the contour of the device housing. Whether it is a smartwatch, a car dashboard, or a smart home hub, the screen becomes an integral part of the surface rather than an inset component. This creates a cleaner industrial design language where the boundary between "hardware" and "interface" blurs, offering a premium, monolithic aesthetic that rigid glass interrupts.

C. Shape and Edge Storytelling

Rectangles are efficient for manufacturing, but they are rarely the best shape for human interaction or storytelling. Flexible OLEDs support aggressive cutting and shaping, enabling circular, elliptical, or free-form displays that match the product’s identity. More importantly, this flexibility allows for "edge storytelling." By curving the display around the side of a device, designers can create ambient notification zones, volume controls, or status indicators that are visible even when the main screen is obscured. This gives the User Interface (UI) a sense of directionality and flow, reinforcing the hierarchy of information from the edge to the center.

D. Mounting and Integration Agility

Rigid displays require specific mounting points and flat surfaces, which often force internal components to be rearranged inefficiently. The inherent flexibility of polyimide substrates allows for more creative mounting solutions. A flexible display can be routed over internal structural ribs, or slightly curved to avoid a camera module or sensor array. While this freedom does not necessarily make the engineering process easier—it often introduces new validation challenges—it allows the mechanical structure to be optimized for durability and space, rather than being dictated solely by the fragility of the screen.

Application Scenarios: Not for Bending, But For...

To understand the real-world impact, we must look beyond the "fold" and see how static curvature solves specific industry pain points.

-

Wearables: It is not for bending; it is for ergonomics. The human wrist is not flat. A curved display wraps around the wrist, reducing the perceived bulk of the device and ensuring that sensors maintain better contact with the skin. It transforms a gadget strapped on the body into technology that fits to the body.

-

Automotive: It is not for bending; it is for immersion and safety. A flat tablet bolted to a dashboard looks like an afterthought. Flexible OLEDs allow for "cockpit surfaces" that curve toward the driver, improving reachability and visibility while minimizing glare. The display follows the interior trim, creating a seamless flow from the instrument cluster to the center console.

-

Industrial & Medical: It is not for bending; it is for compact efficiency. Handheld medical scanners and industrial control units often need to fit into tight housings or distinctive ergonomic grips. A flexible display can conform to a rounded handle or a compact housing, maximizing the viewable area without increasing the device's footprint.

-

Handheld Devices: It is not for bending; it is for grip-friendly forms. As devices get larger, they become harder to hold. By curving the edges of the display, manufacturers can narrow the physical width of the phone or controller, making it fit more comfortably in the palm while maintaining a massive diagonal screen size.

The System Design Reality: Form-Factor Freedom is Earned

A common misconception among product teams is treating Flexible OLED as a "drop-in replacement" for rigid panels. This is a dangerous oversimplification. You are not just selecting a screen; you are engineering a complete display system.

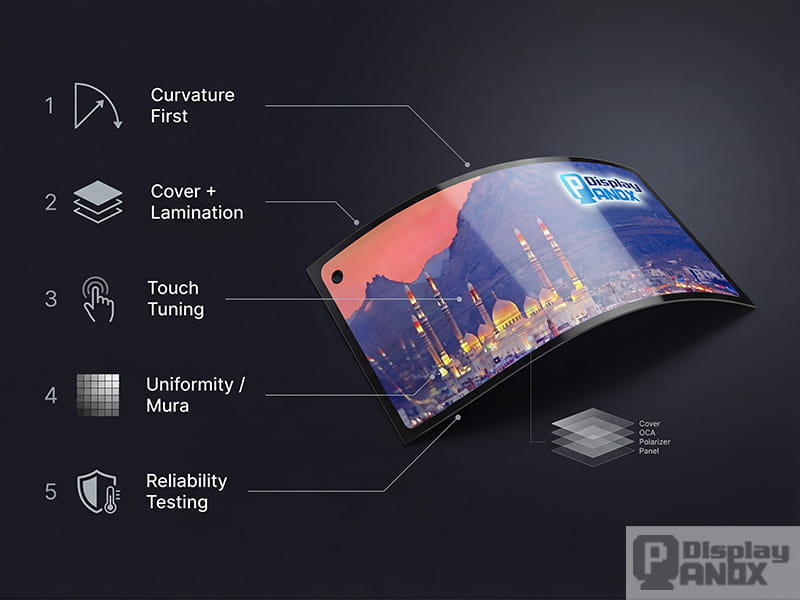

Achieving a non-planar form factor requires a holistic approach to the entire stack. The cover lens (often 3D glass or plastic), the optically clear adhesives (OCA), the touch sensor layers, and the mechanical support structure must all share the same curvature and thermal expansion properties. If one layer fights the curvature, the system will fail due to delamination or stress fractures. Form-factor freedom is earned through integration. It requires a shift from buying components to designing unified electro-mechanical systems.

5 Rules for Designers and Product Managers

For teams looking to leverage flexible OLEDs for static curvature designs, here is a checklist to transition from concept to reliable mass production.

-

Define Target Curvature Early: Do not wait until the Industrial Design (ID) is frozen. The curvature radius (R) dictates the stress levels on the panel. Defining this early allows the panel vendor to optimize the neutral plane design to prevent cracking.

-

Treat Cover & Lamination as Visual Elements: The lamination process on a curved surface is exponentially harder than on a flat one. Ensure your manufacturing partner has the tooling capability for vacuum lamination on 3D surfaces to avoid bubbles and yield loss.

-

Plan for Touch Behavior on Curves: Curved edges introduce "ghost touches" from the user’s palm. The touch IC firmware must be tuned specifically for the curvature to reject false inputs while remaining sensitive to intentional edge gestures.

-

Expect Uniformity Challenges: OLEDs can exhibit color shifts when viewed off-angle. On a curved screen, the user is always viewing some part of the screen at an angle. Design your UI (User Interface) to avoid solid grey backgrounds in curved areas, which can highlight "mura" or color shifting.

-

Build Around Reliability Realities: A bent state creates permanent mechanical stress. You must validate for thermal shock and humidity (RA testing) specifically in the curved state. Ensure your adhesive selection can withstand these environmental changes without pulling the panel apart.

Learn more: Technological Breakthrough! Flexible OLED Luminous Efficiency Surges by 370%

Conclusion

The era of "flat" is rapidly becoming a design choice rather than a technological limitation. Flexible OLED offers a path to products that are more organic, more efficient, and more integrated. However, realizing this potential requires looking past the hype of foldable phones and focusing on the subtle, structural revolutions that polyimide substrates enable.

If you need to source reliable components for your next breakthrough product, see how our Flexible OLED technology can support your design vision.

|