In modern product design, the display is no longer just a component; it is the defining feature of the user interface. While rigid LCDs and OLEDs have served the industry well, the demand for ergonomic integration and futuristic aesthetics has pushed engineers toward Flexible OLED technology.

Flexible OLEDs do more than just bend. They fundamentally alter the constraints of hardware design, allowing for thinner profiles, non-rectangular shapes, and superior optical bonding. This guide explores the architectural advantages of flexible OLEDs and provides engineering insights for integrating them into your next project.

1. The Anatomy of Thinness: Rigid vs. Flexible Architecture

To understand why flexible OLEDs achieve superior thinness, we must look at the substrate and encapsulation layers. The difference is not merely in dimensions, but in materials.

In a traditional Rigid OLED, the organic layers are sandwiched between two glass substrates—a TFT backplane glass and an encapsulation glass. While effective, glass has a minimum thickness limit and is inherently brittle.

Flexible OLEDs replace the glass substrate with Polyimide (PI).

PI is a highly durable plastic material that is coated as a liquid and cured into a film. This switch yields two massive structural advantages:

-

Substrate Reduction: The PI layer is significantly thinner than glass, often measuring in microns rather than millimeters.

-

Encapsulation Evolution: Instead of a thick cover glass, flexible OLEDs utilize Thin-Film Encapsulation (TFE). TFE consists of alternating organic and inorganic layers that protect the pixels from moisture and oxygen without adding bulk.

When you combine the removal of the backlight unit (inherent to all OLEDs) with the removal of rigid glass, you achieve a display module that is paper-thin and lightweight, freeing up critical internal volume for larger batteries or vital sensors.

Browse our complete catalog of Flexible OLED modules to find the perfect fit for your design.

2. Beyond the Rectangle: 5 Custom Form Factors

The laser-cutting capabilities associated with Polyimide substrates allow for shapes that would shatter glass. Flexible OLEDs enable designers to break free from the "black rectangle" paradigm through five distinct implementation forms:

Rounded & Free-Form Corners

Standard displays have sharp 90-degree corners that waste bezel space. Flexible OLEDs can be cut with perfectly rounded corners (R-corners) to match the hardware chassis, maximizing the active display area (AA) relative to the body size.

Notches and Holes

For devices requiring cameras or sensors within the screen area, flexible OLEDs support precise laser cutting. Whether it is a "punch-hole" for a camera or a "notch" for sensors, these cutouts are achieved without the structural instability that drilling into glass would cause.

Fixed-Curved Surfaces (Concave/Convex)

This is the most common application in automotive and wearables. The screen is permanently bonded to a curved surface. This matches the natural curvature of the human wrist or the ergonomic sweep of a vehicle dashboard, improving both reachability and viewing angles.

Waterfall & Side-Edges

By extending the active display area over the side of the device (approximately 88° to 90°), designers can replace physical buttons with virtual side-touch controls. This creates a seamless, bezel-less visual experience where the content appears to flow over the edge like a waterfall.

Wrap-Around & Ring Designs

In specialized industrial or consumer applications, the flexibility of the PI substrate allows the display to wrap entirely around a cylindrical object or form a ring. This creates 360-degree visibility, ideal for smart speakers or omnidirectional indicators.

3. The Value of Optical Bonding: Thin, Bright, and Stable

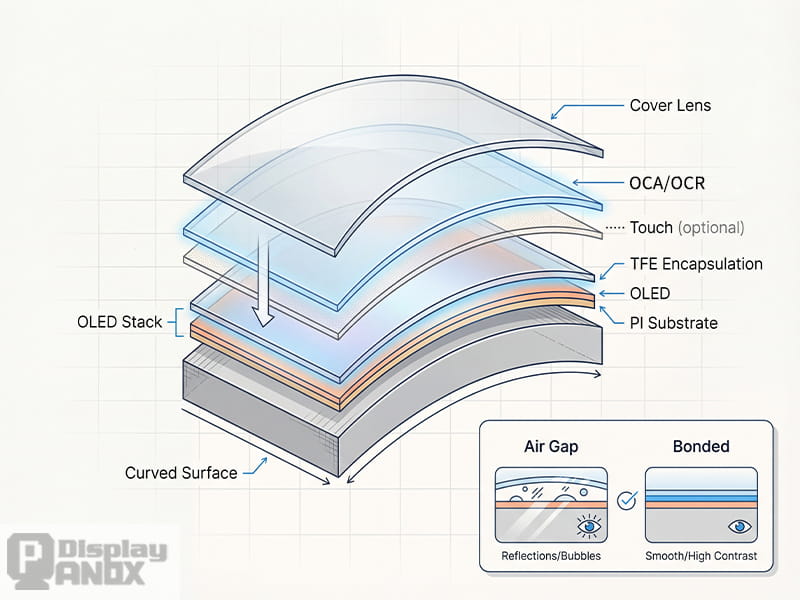

Optical Bonding Layer Stack (Flexible OLED on Curved Surface)

Achieving a premium look isn't just about the display panel; it's about how that panel is bonded to the cover lens. Flexible OLEDs are particularly suited for full lamination (Optical Bonding) rather than air-bonding.

-

Eliminating Parallax: Because the display layers are so thin, full lamination reduces the gap between the touch surface and the pixel to near zero. This makes icons look like they are painted on the surface rather than floating underneath it.

-

Superior Outdoor Visibility: By eliminating the air gap, we remove internal reflection surfaces. This significantly improves the contrast ratio in bright sunlight, ensuring the display remains readable without driving brightness to power-draining levels.

-

Thinner Total Stack: Optical bonding adhesive (OCA/OCR) is microscopic. When combined with a flexible OLED, the total module thickness remains ultra-low, which is critical for sleek industrial designs where every millimeter counts.

Learn more: Flexible OLED Is a Stack Problem: Cover Window, OCA, and Reliability

4. Reality Check: Flexible Does Not Mean "Indestructible"

A common misconception is that "flexible" implies the screen can be crumpled like paper. This is false.

The Bending Radius (R) is the definitive limit.

Every flexible panel has a specific minimum bending radius (e.g., R1.5mm or R3mm).

-

Static Bending: If you bond the screen to a surface with a curvature tighter than its rated R, you risk cracking the inorganic barrier layers within the TFE.

-

Dynamic Bending: For foldables, the hinge design must ensure the screen never compresses beyond this radius.

Exceeding the rated curvature leads to encapsulation failure, resulting in black spots (pixel death due to oxidation) appearing days or weeks after assembly.

5. Engineering Pitfalls: 4 Challenges in Flexible Bonding

Integrating a flexible display requires handling mechanical stress differently than rigid screens. Engineers must anticipate these four common failure points:

1. Neutral Layer Management

When a material bends, the outer surface stretches (tension) and the inner surface compresses. The "Neutral Layer" is the zone in the middle where stress is zero. The design goal is to position the fragile OLED backplane exactly at this neutral layer to minimize mechanical stress on the circuitry.

2. Edge Peeling and Warping

Flexible materials have a "memory" and will try to return to a flat state. If the adhesive strength is insufficient at the curved edges, the screen will delaminate. This requires using high-performance Pressure Sensitive Adhesives (PSA) specifically formulated for curved lamination.

3. Adhesive Selection (OCA vs. OCR)

While Optical Clear Adhesive (OCA) tape is cleaner to handle, Optical Clear Resin (OCR) liquid often fills complex 3D curvatures better. However, OCR requires precise damming to prevent overflow. The choice depends on the complexity of the curve and the yield rate requirements.

4. FPC Bending Zone Vulnerability

The Flexible Printed Circuit (FPC) connection point is the most fragile part of the module. In flexible designs, this area is often bent 180° (COP - Chip on Plastic) to hide the driver IC. This bending zone needs extra reinforcement and precise clearance in the housing to prevent tearing during assembly.

6. Application Scenarios: Where to Use Flexible OLEDs?

-

Smart Wearables: Wristbands and watches where rigid screens create bulky, uncomfortable "pucks" on the wrist.

-

Automotive Interiors: Curved center consoles and digital cockpits that need to flow with the dashboard geometry rather than sitting flat against it.

-

Medical Handhelds: Devices requiring ergonomic, rounded grips where a flat screen would force a boxy, unergonomic housing.

-

Industrial HMI: Control knobs with integrated displays or equipment with curved surfaces where flat panels are difficult to mount.

7. The Selection Rule of Thumb

How do you decide between Rigid and Flexible? Use this simple logic:

"If your design requires a curvature radius under 500mm, a non-rectangular active area, or the absolute thinnest profile possible, prioritize Flexible OLED."

Ready to innovate?

Flexible OLEDs offer the highest degree of design freedom in the display market today. If you are developing a product that requires a custom shape or ultra-thin profile, explore our complete catalog of commercial-grade flexible display modules.

| Model | Size(inch) | Display Type | Resolution | Interface | Display Brand |

| 1.39 inch Round/Circular OLED Flexible For Wearable Smartwatch | 1.39 | AMOLED | 400(RGB)×400 | MIPI | Innolux |

| 1.5 inch Flexible OLED For Wearable Smart Watch | 1.5 | AMOLED | 120(RGB)×240 180PPI | SPI, MIPI | Innolux |

| 1.8 inch Flexible PMOLED For Wearable Bracelet | 1.8 | PMOLED | 160×32 | SPI | Futaba |

| 5.1 inch Flexible OLED On-Cell PACP For Cellphone | 5.1 | AMOLED | 720(RGB)×1520 330PPI | MIPI | BOE |

| 5.99 inch Flexible OLED On-Cell PACP For Cellphone | 5.99 inch | AMOLED | 1080(RGB)×2160 329PPI | MIPI | BOE |

| 5.99-Inch 1440x2880 Flexible AMOLED Display | BOE OLED for Huawei Smartphone | 5.99 | AM-OLED, OLED | 1440 x 2880 | MIPI | BOE&Huawei |

| 6.52 inch Flexible OLED 2520x840 Touch Panel | 6.52 | AM-OLED, OLED | 2520(RGB)×840 407 PPI | MIPI | CSOT |

| 6.67inch Flexible AMOLED 2K for Smartphone | 6.67 | OLED, AM-OLED | 1080x 2400 | MIPI | Tianma |

| 7.8 inch Flexible Full Color OLED 1920x1440 MIPI | 7.8 | AMOLED | 1440 x 1920 | MIPI | Royole |

| 8 inch Flexible/Foldable OLED | 8.01 | AMOLED | 2480x1860 | MIPI | CSOT |

| 13.3 inch 1536 x 2048 Flexible OLED Touch Screen | 13.3 | AM-OLED, OLED | 1536 (H) × 2048 (V) | eDP | LG |