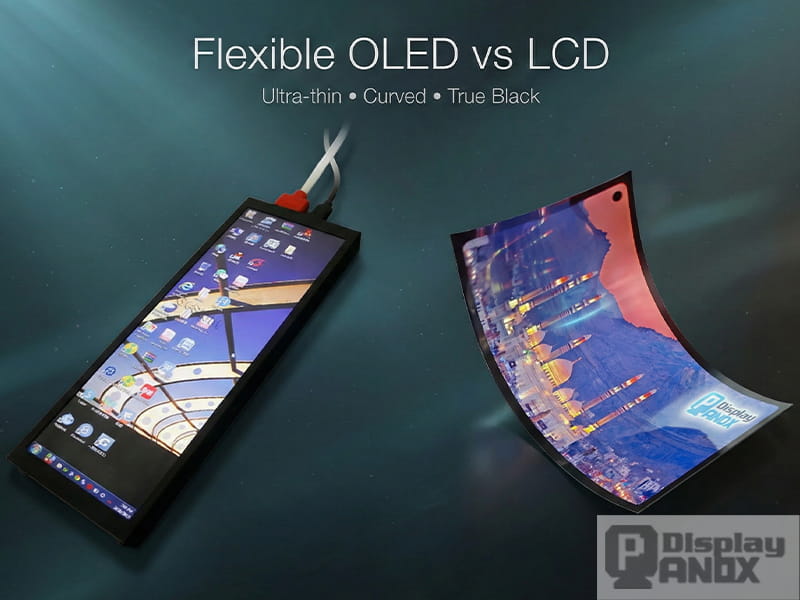

In the competitive landscape of hardware design, the choice between Flexible OLED and LCD is rarely just about cost—it is about defining the physical constraints and aesthetic potential of the final product. While LCD remains a stalwart for cost-effective, high-brightness applications, Flexible OLED has emerged as the distinct winner for engineers and designers pushing the boundaries of form factor.

Below, we analyze the architectural differences and design implications to help you decide when to make the switch.

Learn more: Why Flexible OLED Displays Are Ideal for Ultra-Thin, Curved & Custom-Shaped Designs

The Bottom Line: When is OLED the Superior Choice?

Before diving into the stack structures, let's establish the clear use cases where Flexible OLED outperforms LCD. If your product roadmap prioritizes physical minimalism or non-standard shapes, LCD technologies often hit a "physical wall" that only OLED can bypass.

-

Ultra-Thin Profiles & Z-Height Constraints: When every millimeter of internal volume counts—such as in wearables, foldables, or ultra-slim tablets—Flexible OLED is the superior candidate. By eliminating the backlight unit (BLU), you gain critical space for larger batteries or thinner enclosures.

-

Curved Surfaces & 3D Contours: If the design requires the display to wrap around a wrist, cascade over an edge (waterfall display), or fit a non-rectangular dashboard, Flexible OLED is essential. Its ability to utilize plastic substrates allows it to conform to curves that would shatter the glass layers required by LCDs.

-

High-Contrast & "Dark Mode" UIs: For devices that demand "True Black" visuals or rely heavily on dark user interfaces to convey a premium feel, OLED’s self-emissive nature provides a contrast ratio that LCDs cannot mathematically achieve due to light leakage.

1. Structural Stacking: The Engineering of Thinness

The most immediate engineering difference between these two technologies lies in their vertical stacking. This is not merely a specification difference; it is a fundamental shift in how the display generates images.

LCD (Liquid Crystal Display) is a transmissive technology. It functions like a complex shutter system that requires a dedicated light source. The stack includes the Backlight Unit (BLU), diffusers, polarizers, the liquid crystal layer, and color filters. Even with advancements like Mini-LED, the necessity of a physical light source and the gap required for optical diffusion imposes a hard limit on minimum thickness.

OLED (Organic Light Emitting Diode), conversely, is self-emissive. Each pixel generates its own light when current passes through the organic layers. This eliminates the need for the bulky backlight unit entirely. Consequently, an OLED module can be significantly thinner and lighter than a comparable LCD module. For product architects, this reduction in "Z-height" simplifies mechanical integration and reduces the overall weight of the device.

2. Curved & Custom-Shaped: Breaking the Glass Ceiling

While rigid OLEDs exist, Flexible OLEDs are the game-changer for modern industrial design because they replace the rigid glass substrate with a flexible plastic material, typically Polyimide (PI).

LCDs are notoriously difficult to curve permanently and effectively impossible to bend dynamically. The liquid crystal layer requires a consistent cell gap to maintain image uniformity; bending an LCD disturbs this gap, leading to color pooling and image distortion. Furthermore, the glass substrates and multiple optical sheets in the backlight stack are prone to cracking under stress.

Flexible OLEDs inherently support dynamic bending and static curvature. Because the emissive layer is solid-state and printed on a flexible PI substrate, the display can withstand significant mechanical deformation without breaking or distorting the image. This reliability is backed by rigorous mechanical deformation testing, including bending radius tests (e.g., R1.5mm for foldables), twisting tests, and rolling tests. If your design calls for a wrap-around screen or an odd-shaped active area (such as a circular watch face or a notched instrument cluster), Flexible OLED offers the manufacturing tolerance to achieve it.

3. Visual Performance: Contrast, Angles, and Response

From a User Interface (UI) and User Experience (UX) perspective, the choice of display dictates how "alive" the content feels. The visual superiority of OLED stems from its ability to control light at the pixel level.

-

True Black & Infinite Contrast: In an LCD, black is merely "blocked light." Even the best LCDs suffer from light leakage, turning black backgrounds into a dark gray, especially in low-light environments. OLEDs simply turn the pixel off. This results in "True Black" and a virtually infinite contrast ratio, making colors pop and creating a seamless blend between the display and the device’s bezels.

-

Viewing Angles & Response Time: OLEDs generally offer wider viewing angles with less color shift compared to standard TN or IPS LCD panels. Furthermore, OLEDs have a near-instantaneous response time (often under 0.1ms), virtually eliminating motion blur in high-speed content or fluid UI animations.

4. Power Consumption: Variable vs. Constant

The power dynamic between the two technologies is nuanced and depends entirely on the content being displayed. Understanding this is crucial for battery life optimization.

LCD power consumption is relatively constant. Because the backlight must be on regardless of whether the screen is showing a white document or a black terminal window, the energy draw is static (varying mostly with brightness settings).

OLED power consumption is content-dependent. Since each pixel is individually powered, displaying white draws maximum power, while displaying black draws almost zero. For devices utilizing Dark Mode system-wide or featuring high-contrast interfaces with deep blacks, OLED is significantly more energy-efficient. However, for applications displaying predominantly white backgrounds (like word processing), OLED may consume more power than an optimized LCD.

Review our Flexible OLED portfolio to match your design targets in thickness, curvature, and contrast.

5. The Balanced View: Cost, Longevity, and Trade-offs

To make an informed engineering decision, we must acknowledge where LCDs still hold the advantage and where OLED requires careful management.

The Case for LCD:

-

Cost Efficiency: LCD manufacturing is a mature, high-yield process. For budget-sensitive projects or massive displays where thinness is not critical, LCD is undeniably the more economical choice.

-

Sustained High Brightness: In direct sunlight outdoor applications, high-end LCDs can often sustain peak brightness levels longer without thermal throttling compared to OLEDs.

-

Longevity: LCDs rely on inorganic materials that are less prone to degradation over decades.

OLED Considerations:

-

Burn-in Risk: Static UI elements (like taskbars or HUDs) can cause uneven wear on organic pixels over time, leading to "burn-in." Modern pixel-shifting algorithms have mitigated this, but it remains a consideration for fixed-interface devices.

-

Encapsulation: Organic materials are highly sensitive to moisture and oxygen. Flexible OLEDs require advanced Thin-Film Encapsulation (TFE) to ensure reliability, which adds complexity to the manufacturing process.

Conclusion

The transition from LCD to Flexible OLED is not merely an upgrade—it is a design enabler. If your project demands a rigid, standard aspect ratio and cost optimization, LCD remains a powerful workhorse. However, if your goal is to achieve an ultra-thin profile, immersive high-contrast visuals, or a curved form factor that defies traditional geometry, Flexible OLED is the only technology capable of bringing that vision to reality.

Browse our complete catalog of Flexible OLED modules to find the perfect fit for your design.

| Model | Size(inch) | Display Type | Resolution | Interface | Display Brand |

| 1.39 inch Round/Circular OLED Flexible For Wearable Smartwatch | 1.39 | AMOLED | 400(RGB)×400 | MIPI | Innolux |

| 1.5 inch Flexible OLED For Wearable Smart Watch | 1.5 | AMOLED | 120(RGB)×240 180PPI | SPI, MIPI | Innolux |

| 1.8 inch Flexible PMOLED For Wearable Bracelet | 1.8 | PMOLED | 160×32 | SPI | Futaba |

| 5.1 inch Flexible OLED On-Cell PACP For Cellphone | 5.1 | AMOLED | 720(RGB)×1520 330PPI | MIPI | BOE |

| 5.99 inch Flexible OLED On-Cell PACP For Cellphone | 5.99 inch | AMOLED | 1080(RGB)×2160 329PPI | MIPI | BOE |

| 5.99-Inch 1440x2880 Flexible AMOLED Display | BOE OLED for Huawei Smartphone | 5.99 | AM-OLED, OLED | 1440 x 2880 | MIPI | BOE&Huawei |

| 6.52 inch Flexible OLED 2520x840 Touch Panel | 6.52 | AM-OLED, OLED | 2520(RGB)×840 407 PPI | MIPI | CSOT |

| 6.67inch Flexible AMOLED 2K for Smartphone | 6.67 | OLED, AM-OLED | 1080x 2400 | MIPI | Tianma |

| 7.8 inch Flexible Full Color OLED 1920x1440 MIPI | 7.8 | AMOLED | 1440 x 1920 | MIPI | Royole |

| 8 inch Flexible/Foldable OLED | 8.01 | AMOLED | 2480x1860 | MIPI | CSOT |

| 13.3 inch 1536 x 2048 Flexible OLED Touch Screen | 13.3 | AM-OLED, OLED | 1536 (H) × 2048 (V) | eDP | LG |