ffc vs fpc cables split screen hero

Flat Flexible Cables (FFCs) and Flexible Printed Circuits (FPCs) are two widely used flexible interconnect solutions for connecting electronic components when rigid wiring is too bulky or cannot bend reliably. Because both are thin, bendable, and visually similar at a glance, they are often confused. In reality, they differ in structure, capability, and best-fit applications. Choosing the right option depends on how complex your connection needs to be, how frequently it must move, and what environmental conditions it will face.

Learn more:FPC Connectors For Display Panel

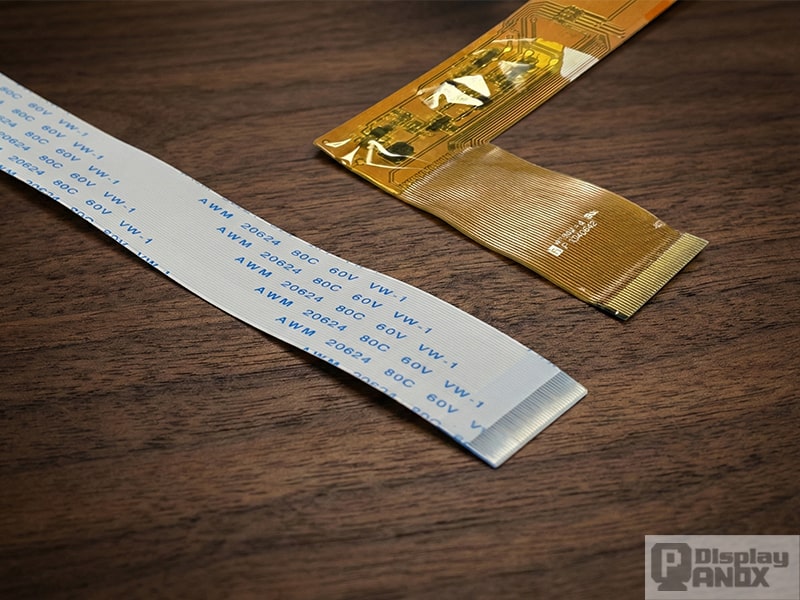

What Is an FFC (Flat Flexible Cable)

An FFC is best understood as a straightforward point-to-point interconnect. It is made of multiple flat conductors arranged in parallel, laminated within an insulating film so the cable can bend and route through tight spaces. A common way to describe FFCs is by contact orientation: in one style, the exposed contacts on both ends are on the same side of the cable, while in another style, the contacts on one end are on the opposite side compared with the other end. This matters when the mating connectors or the mechanical layout require a “flip” in orientation.Structurally, an FFC relies on its parallel conductors and the contact pads at each end to carry signals directly from one device to another. Practical parameters typically include pitch (the spacing between adjacent contacts, which determines connector compatibility) and end reinforcement (often a stiffener that helps insertion and reduces wear at the connector interface). Many FFCs use copper conductors, plated contact areas, and flexible polyester insulation, designed for convenient routing and repeated bending in moderate conditions.

The biggest advantage of an FFC is simplicity. Each conductor maps directly across the cable, which makes installation fast and design integration straightforward. FFCs are usually flexible, easy to disconnect and reconnect, and cost-effective. The tradeoff is that they are not intended for complex circuitry or advanced routing, and in harsh environments they may be less durable than an FPC.

FFCs are commonly found inside consumer electronics such as laptops, printers, and monitors, as well as in cameras where sensors connect to processing boards. They are also used in robotics for moving joints, and appear in automotive dashboards and infotainment systems, medical devices, industrial automation equipment, and home appliances wherever a simple and reliable internal connection is required.

ffc connecting lcd module to board demo

What Is an FPC (Flexible Printed Circuit)

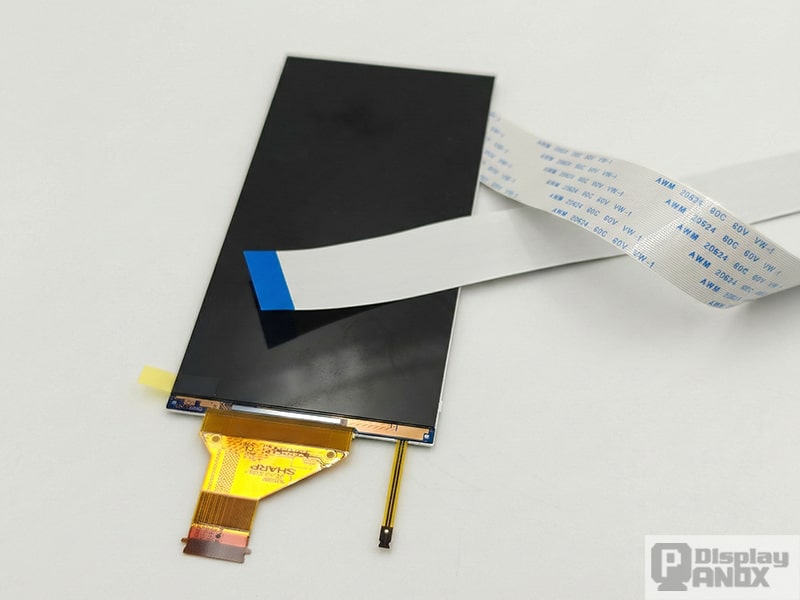

An FPC is closer to a flexible version of a printed circuit board. Instead of parallel wires, it uses etched copper traces on a flexible substrate, enabling complex routing and, when needed, multilayer designs. This makes an FPC ideal for compact products where the interconnect must fold, wrap, or conform to irregular shapes. Unlike an FFC, which can be relatively interchangeable when pitch and pin count match, many FPCs are customized for a specific product because the trace layout is designed around the device’s mechanical and electrical requirements.A typical FPC includes contact pads with a defined pinout, pitch matched to the connector, and sometimes vias to connect traces between layers. Depending on the design, it may also carry mounted components such as resistors, capacitors, or ICs. Common substrate materials include polyimide or polyester, with copper bonded by adhesives, and a protective coverlay layer for insulation. Optional shielding can be added to reduce EMI, and contact areas may be plated to improve connector reliability.

Functionally, an FPC can behave like a cable, but its signals can follow complex paths, branch to different areas, interact with components mounted on the FPC, or transition between layers. This is what enables higher integration in a smaller footprint. As a result, FPCs are often chosen when you need advanced routing, higher functional complexity, or stronger performance under demanding conditions. The compromise is higher cost and greater design effort, and the finished FPC is typically less reusable across products because it is built for a specific layout and requirement set.

Related: Flexible Display Screen

ffc vs fpc cable closeup

FPCs are widely used in smartphones, tablets, laptops, cameras, and wearables, where tight packaging and precise routing are critical. They are also common in automotive systems such as dashboards, infotainment, and ADAS modules, and in medical, aerospace, defense, and industrial applications where reliability under challenging conditions is a priority.

Key Differences Between FFC and FPC

ffc to fpc interconnect demo with lcd module

The simplest way to separate the two is by complexity. FFCs are parallel-conductor interconnects designed for straightforward 1:1 connections, while FPCs are flexible circuit boards that support complex routing, multilayer structures, and even component integration. In cost-sensitive projects with simple connectivity needs, an FFC is often the practical option. When routing is complex, geometry is constrained, or durability requirements are higher, an FPC is usually the better fit.

How to Choose the Right Option

Start with functional complexity. If your design needs a direct connection without special routing, an FFC is typically sufficient. If you need multilayer routing, specific trace paths, branching, or integrated circuitry, you should lean toward an FPC.Next, consider mechanical movement and space. If the cable must bend frequently but the routing is simple, an FFC can work well and is easy to assemble. If the interconnect must fold into tight or irregular spaces, or must maintain performance under repeated dynamic motion with a tailored shape, an FPC offers more design freedom.

Budget and environment also matter. FFCs are generally lower cost and are common in moderate environments. FPCs cost more due to design and manufacturing complexity, but they are often selected for higher temperatures, chemical exposure, tighter mechanical stress, or higher reliability requirements. Finally, confirm connector compatibility, pitch, and assembly constraints early, because these practical details often decide whether an FFC is feasible or whether an FPC is required.

Conclusion

Both FFCs and FPCs enable flexible interconnections in modern electronics, but they are optimized for different goals. FFCs are best for simple, cost-effective, point-to-point connections that still require flexibility. FPCs are best for compact designs that demand complex routing, customization, and stronger durability under demanding conditions. Once you align the interconnect choice with your project’s complexity, motion profile, environment, space constraints, and cost targets, selecting between FFC and FPC becomes straightforward.Learn more:What Does Panox Display Do ?