Choosing the right LCD can make or break an industrial UI. Legibility at a glance, stable colors across shifts, and predictable performance over years matter more than flashy specs. While all LCDs use liquid crystals to control light, the panel technology behind the display heavily influences viewing angles, contrast, motion clarity, and long-term reliability. This guide explains the main types of LCD and how to pick the best fit for real-world devices.

1 The main types of LCD panels: TN, VA, and IPS

TN (Twisted Nematic): fast and affordable, but visually limited

TN is widely used because it’s cost-effective and responds quickly. If your product displays basic information and will be viewed from a consistent angle, TN can be a workable option.Trade-offs: color shifts are noticeable, viewing angles are tight (especially vertically), and color accuracy is typically the weakest of the three.

Best for: simple instruments, budget devices, fixed-angle HMIs.

---

VA (Vertical Alignment): high contrast and deep blacks

VA panels are known for strong contrast and darker blacks, which can improve readability for certain dashboards and data-focused screens.Trade-offs: motion can smear slightly in fast transitions, and response is usually slower than TN.

Best for: control panels, dashboards, industrial info displays where contrast is a priority.

---

IPS (In-Plane Switching): stable color + wide viewing angles

IPS is often the “safe” professional choice—colors stay consistent and the image remains readable even when viewed off-axis. For operator panels or medical interfaces where multiple people view the screen from different positions, IPS can noticeably reduce misreads and eye strain.Trade-offs: typically higher cost than TN/VA, though often justified by consistency and lifecycle expectations.

Best for: medical devices, professional equipment, multi-angle HMIs, mobile terminals.

2 TN vs VA vs IPS: quick comparison

|

|---|

3 Standard (passive) LCD vs TFT LCD: why it matters

You’ll often see “LCD” used broadly, but there’s a major practical difference between passive-matrix panels (like STN/DSTN) and active-matrix TFT LCD.

Related:Click here to view more TFT-LCD display products.

Passive LCD (e.g., STN/DSTN)

These panels address pixels through a shared row/column method. They can be sufficient for very basic readouts, but they usually have slower transitions and limited image quality.Common limitations: slower response, lower brightness, simpler visuals.

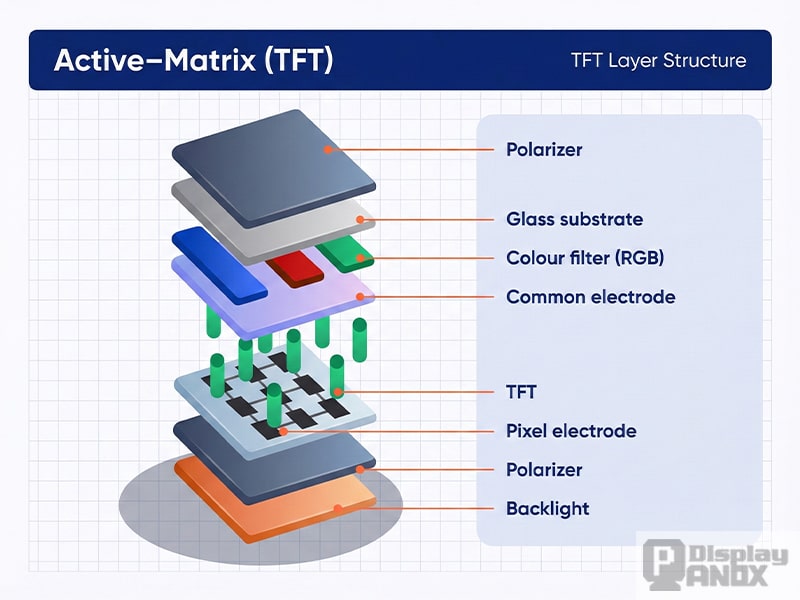

TFT LCD (active matrix)

In a TFT LCD, each pixel is driven more precisely (via a transistor at each pixel), enabling stronger brightness, better control of color, improved motion performance, and easier integration with modern touch solutions and optical bonding.Why it matters in industrial use: TFT tends to deliver a more stable image in demanding environments and supports more advanced interface designs.

4 Passive vs active matrix: the core idea (simple version)

Passive-matrix LCD: lower brightness and speed, suitable for minimal information displays.Active-matrix (TFT): higher performance across brightness, color control, and response; the modern default for professional applications.

5 How to choose the right panel: a checklist that actually helps

When selecting among the types of LCD, don’t start with buzzwords—start with constraints:· Viewing angles & color stability: Will operators view from the side? From above/below?

· Brightness & contrast: Is it used under strong ambient light? In a vehicle? Near windows?

· Motion clarity: Do you show scrolling graphs, animations, camera feeds, or fast UI transitions?

· Operating temperature range: Hot enclosures, cold storage, outdoor equipment.

· Backlight lifespan & uniformity: Long-duty operation needs predictable backlight behavior.

· Touch compatibility: capacitive/resistive, cover lens thickness, optical bonding requirements.

· Supply stability & lifecycle: industrial devices often demand years of availability.

If you expect varied viewing angles and consistent readability, TFT IPS is frequently the most dependable long-term pick.

6 Common LCD myths (and what to believe instead)

“TFT is always expensive.” The cost gap has narrowed, and total ownership cost can favor TFT due to stability and reduced field issues.“LCD is outdated.” LCD remains dominant in many industrial/professional products because it’s predictable, customizable, and mature.

“If specs match, quality matches.” Not necessarily—real differences appear in backlight durability, environmental tolerance, and consistency across production.

Learn more: LCD vs LED vs OLED vs Micro LED vs Micro OLED

Closing thought

Understanding the *types of LCD* isn’t about memorizing acronyms—it’s about preventing avoidable failures: washed-out screens, unreadable angles, premature backlight wear, and inconsistent colors across units. Pick the panel tech that matches your environment and lifecycle expectations, and your UI will stay readable long after the launch hype is gone.If you’re looking for a high-performance TFT-LCD display products, we offer a full range of products for you to choose from.