Regular LED

Organic LED(OLED)

How OLED works

Ok so to explain how OLED works in the first place, I'm going to have to get into some physics. It's pretty complicated stuff, but I'll do my best to simplify it based on how I understand it myself. Admittedly, I'm not an expert on this stuff, so don't hate me if I make some small errors or leave something out, you can just let me know in the comments. Alright, so, you might remember from school that atoms have layers of electrons surrounding them, called 'shells', and how each shell has different levels of energy depending on how close they are to the nucleus. You may also remember that electrons can actually be shared between atoms, for example with covalent bonds. Also, electrons can be 'delocalized', which means they're not really closely associated or 'stuck' with any atom in particular. So if you have a crystal lattice of many molecules near each other, these molecules may sort of share electrons and pass them around. These are also called "free electrons”, and are often a big factor in how electrically conductive a material is. Alright so now we have some context, but what does this have to do with OLED? You see molecules used in OLED are special because they emit light when a current is passed through them. How this happens is when current passes through them, it adds energy which is absorbed by those molecules and their electrons. This kicks some electrons into a higher energy layer of the electron shell, known as the conduction layer. When this happens, this leaves an 'electron hole' in the lower energy level, or the valence shell, where the electron was - simple enough. There is a lot more physics in this bit that I could possibly get into, but if you want, you can get more details if you look up the Wikipedia page for 'Excitons', which is the name for this combination of an electron and electron-hole. Anyway, eventually this excited state of the outer electron decays, and the electron falls back down from the higher energy to lower energy level, and in doing so releases its extra energy in the form of a photon or light. This is called 'recombination', and the color of the photon depends on how much energy is released, which in turn depends on the molecule or material.

OLED Products From Panox Display

Why Use OLED At All

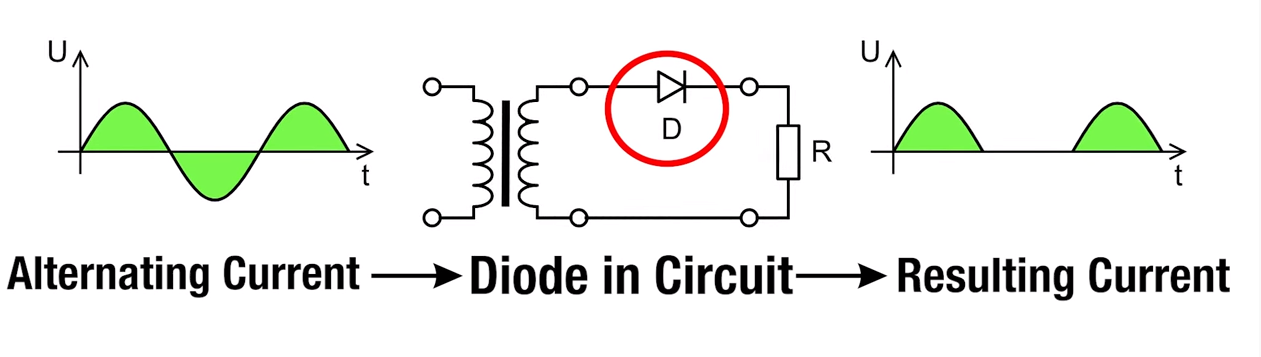

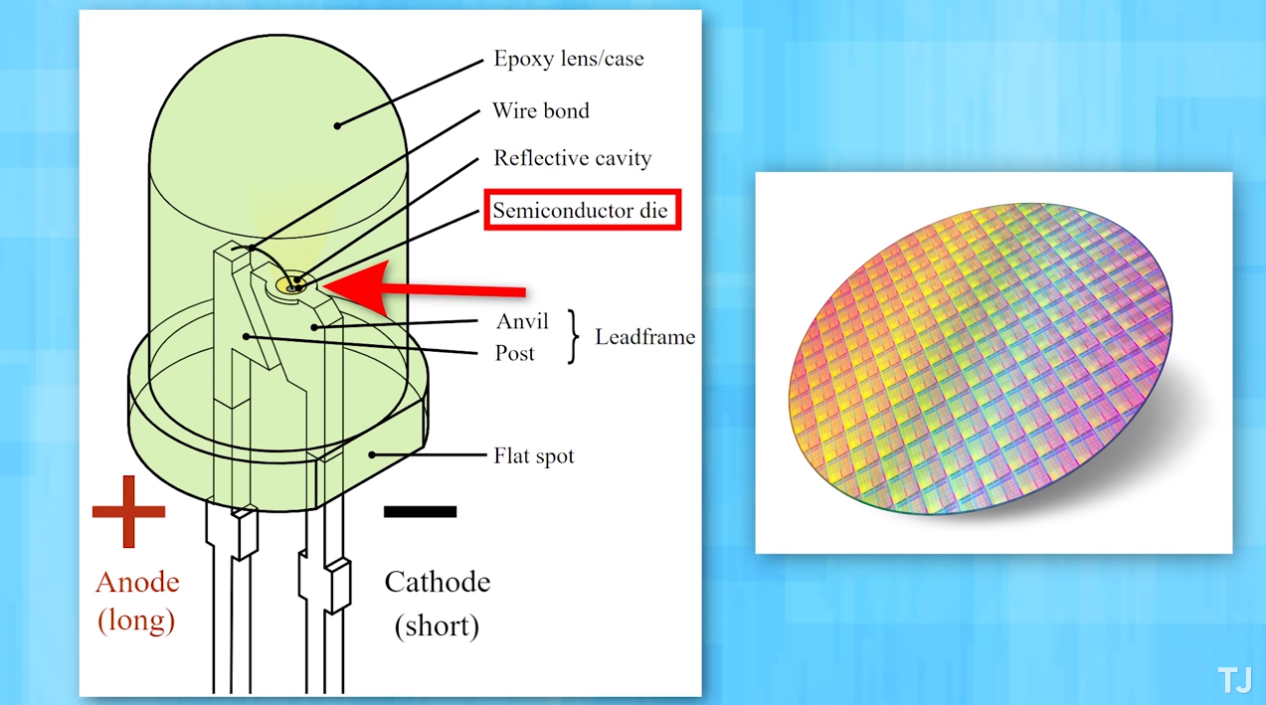

So why use organic molecules at all then? Why not use regular inorganic LEDs? Well, we do, but only for huge displays, and it comes down to the difficulty of manufacturing LEDs at very small sizes. Typically LEDs are individually made components, each cut from a piece of semiconductor, so they have to be constructed and placed on the panel one by one. Even for a 1080p screen, that's 2 million pixels, which will take a long time to make, and then you have all the RGB sub-pixels, so really it's 3 times that. You also have to have a way to wire up all these LEDs, and there's just a ton of room for error. Now like I said, for massive panels like those used on billboards or something, they are viewed very far away, so the LEDs don't have to be very small or close together, so it's easy to make them. But the smaller the screen, the harder it is to pack individual LEDs together as pixels, so it's better to use other technologies like LCD at these high pixel densities.

How OLED Is Made

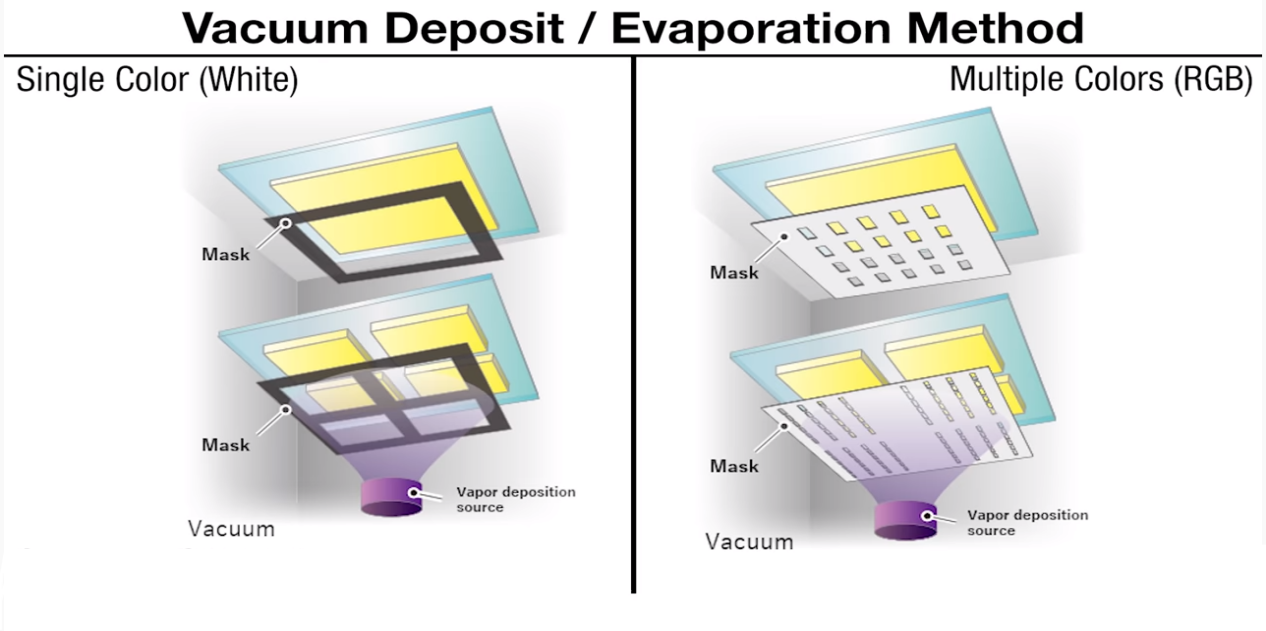

So what is it about how OLEDs are manufactured that makes them able to overcome this issue? Well, OLEDs are manufactured completely differently than regular LEDs. In fact, OLED pixels aren't made of a physical diode with wires and stuff at all. You see with LED, you have to cut it from a wafer, and wire it up to pass current through it. Organic molecules, from my understanding, are a lot easier to manipulate, so instead of using wires to pass current through them, you can just take one conductive sheet, spray OLED molecules onto it, then sandwich it between another conductive sheet, then the whole thing just puts electricity through it so it all lights up. In other words, OLED is deposited as a film between two layers which act as an anode and cathode, when whatever parts of that film get power will light up. This means you can have squares of OLEDs for example that are not really individual points of light, but rather the entire square can light up uniformly. Now to make individual pixels, you just have to find a way to divide up the anode and cathode layers so they can provide voltage to only certain tiny parts of the screen at once. So to make a pixel, you can create what is called a 'matrix' of anode and cathode layers, which is basically a big mesh that lets you choose and energize individual points, one for each pixel. Then you can deposit the OLED material onto the matrix in each spot. And you'll also probably need a way to control which types of OLED molecules you put where, because different molecules emit different colors of light. This can be done in a number of ways, including literally inkjet printing each pixel, so you can control exactly where each type of molecule is deposited. Or, you can put the OLED material into a gas form and then vacuum deposit it, so it's uniformly distributed. Of course remember, the way I'm explaining it is very over-simplified. Anyway, the main takeaway is that OLED is manufactured in a completely different way from LEDs, which is way easier than if you wanted to make tiny regular LEDs of the same size as OLED subpixels.

Micro LED

that do actually use traditional inorganic LEDs being used as individual pixel elements, just like with OLED. If these elements could be shrunk down to what is necessary for say a TV or monitor, it would have the same benefits as OLED, such as not needing a backlight, and having perfect black levels as a result. But it would also have none of the degrading properties of OLED. But Micro LED is still not here yet. Companies like Samsung and LG have made MicroLED TVs, but they have to be huge, like 100 inches plus because the LEDs are still relatively big, therefore the pixel density is still not nearly as good as LCD or OLED. Also, because they are so tough to manufacture and it's a new technology, they are extremely expensive. However, these companies are obviously working on improved methods to shrink the LEDs and improve the speed of making them. I personally think eventually MicroLED will replace OLED, but it will take several years.

That being said though, you may have heard about Micro LED, which I've mentioned before on this channel, and is basically the holy grail of display technology. Micro LED refers to screens

Types of OLED Technology

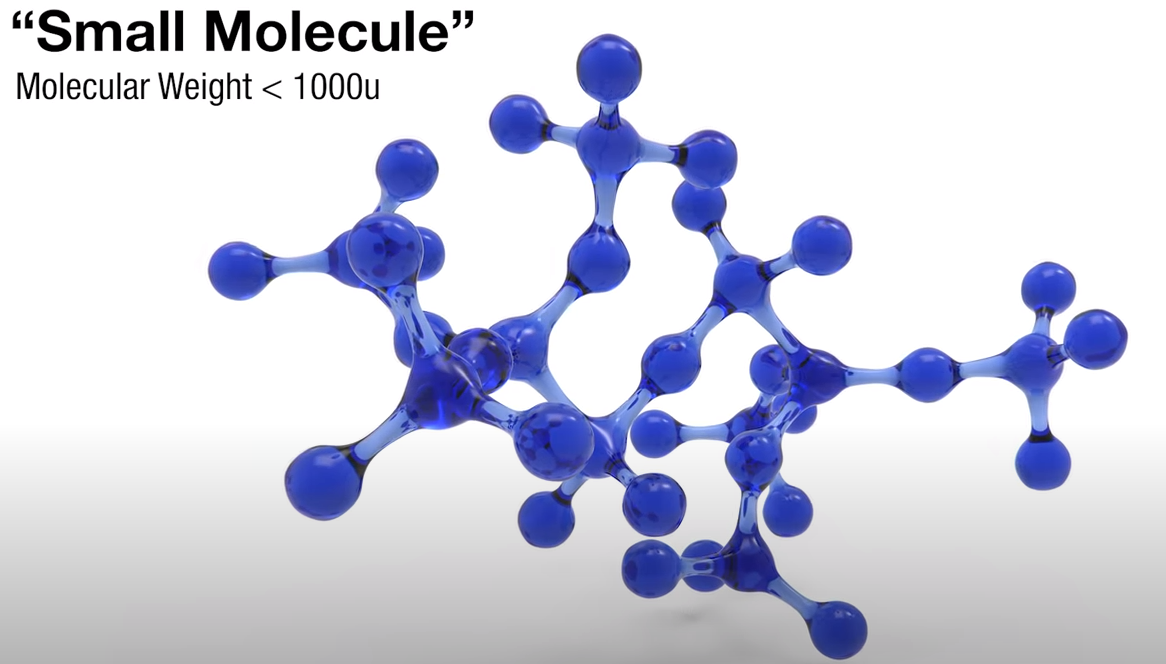

Now, you may be wondering more about these 'organic compounds that are actually used in OLED, and there are several of them used, depending on the tech. The current two major types of OLED technologies in use and development are known as 'Small Molecule' and Polymers. And at least in 2019, basically, all OLEDs were the 'small molecule' type. In this context, a small molecule basically just means it's a carbon-containing molecule that is literally relatively small, specifically having a molecular weight under 1000 or so. On the other hand, polymers are very large molecules formed as long chains, but I'll get to them later. One example of a small molecule used in OLED is... well this name, abbreviated as AlQ3. This molecule contains aluminum and carbon, and is known as an 'organometallic chelate'.That's not really important but it sounds cool. Here, the aluminum is in the middle, surrounded by three branches of "8-hydroxyquinoline". According to a 2006 scientific paper, this organic compound is special because by modifying and substituting certain atoms, you can tune the frequency of light emitted, so it can be used to create various colors spanning the entire visible spectrum. In simpler terms, you can use it to make lots of different colored pixels. That's just one example of a molecule used in some OLED though, there are lots of other potential small molecules. The other type of technology we can talk about is called either PLED or PMOLED and uses light-emitting polymers or LEPs.A polymer is a general term for typically very large molecules with repeating subunits. So basically, a big molecule with a repeating pattern forms a chain. For example, DNA is a polymer, along with nylon, silicone, rubber, and lots else you probably use every day Anyway, PMOLED uses a type of polymer called electroluminescent conductive polymers', which is fancy talk for an organic polymer that lights up when charged with electricity. Apparently, by substituting different so-called 'side chains' on the molecule, you can determine what color it lights up as. Here are some specific polymers used for different colors. There's Polyphenylene, which is a blue emitter.Poly(p-phenylene vinylene) is a green emitter. And Poly(alkyl thiophene) is a red emitter. You can see these show the base pattern, and the brackets indicate it repeats on either side. All that being said though as I mentioned, my understanding is Polymer based OLED is still mostly in the development stage. Finally, there is a third possible type of OLED that is still being explored, called 'Phosphorescent' OLED, or PMOLED. These would work on the principle of phosphorescence, which I'm not going to get into because it would require even more physics I'm not prepared to explain. But a major benefit of this type of OLED would be that it is way more efficient than other forms of OLED. Again though is still apparently pretty early in the research phase. So, by now you should be an OLED expert and probably learned way more than you'll ever need, but hopefully found it interesting.

Where To Buy OLED Display?

A wide variety of OLED bulker options are available to you.

Panox Display offer 100+ OLED panel, about 30% of these are PMOLED, and 70% of these are AMOLED.