In the rapidly evolving landscape of display technology, Organic Light Emitting Diode (OLED) panels have become the gold standard for high-contrast, vibrant visualization. However, for product engineers and procurement managers, simply choosing "OLED" is not enough. The critical decision often comes down to the underlying architecture: Rigid OLED vs. Flexible OLED.

While both technologies utilize self-emissive organic materials to produce images, they differ fundamentally in their substrate materials, manufacturing processes, and final physical properties. This guide explores the technical distinctions between these two panel types to help you determine the right solution for your application.

1. The Core Distinction: Substrate Material

The primary difference between rigid and flexible OLEDs lies in the substrate—the foundation upon which the organic pixels are deposited.

Rigid OLED: The Glass Foundation

Rigid OLED panels are constructed using a glass substrate. Glass is an excellent material for displays because it creates a perfect barrier against moisture and oxygen, which are the primary enemies of organic light-emitting materials. However, the use of glass imposes physical limitations: the panel is inflexible, heavier, and prone to shattering upon impact.

Flexible OLED: The Polyimide Advantage

Flexible OLEDs replace the glass base with a flexible plastic substrate, typically made of Polyimide (PI). Polyimide is a high-performance polymer that offers high heat resistance and excellent mechanical strength. By depositing organic layers onto this film, manufacturers create a display that is not only bendable but also significantly thinner and lighter than its rigid counterpart.

2. Manufacturing and Encapsulation Processes

The shift from glass to plastic necessitates a radically different manufacturing approach, particularly in how the delicate organic layers are protected (encapsulated).

Rigid Encapsulation: Glass Frit Sealing

Manufacturing rigid OLEDs is a mature and cost-effective process. Since the bottom substrate is glass, the top encapsulation layer is also typically a glass lid. Manufacturers use glass frit (a ceramic paste) to fuse the top and bottom glass layers, creating a hermetic seal. This process is straightforward but results in a "sandwich" structure that adds thickness and weight.

Flexible Encapsulation: Thin-Film Encapsulation (TFE)

Flexible OLEDs cannot use a heavy glass lid, as it would break when the screen flexes. Instead, they utilize Thin-Film Encapsulation (TFE).

-

The Process: TFE involves depositing alternating microscopic layers of inorganic materials (to block moisture) and organic materials (to buffer stress and smooth particles) directly over the OLED pixels.

-

Laser Lift-Off (LLO): Since the flexible polyimide liquid starts as a coating on a carrier glass for stability during production, a UV laser is used at the end of the process to detach the flexible film from the carrier glass. This step, known as Laser Lift-Off, is technically demanding and contributes to the higher cost of flexible panels.

3. Physical Performance and Durability

The choice of substrate directly impacts the physical durability and the form factor possibilities of the end product.

Impact Resistance

Rigid OLEDs are inherently brittle. If a device with a rigid OLED is dropped, the display panel itself is likely to crack because the underlying substrate is glass. Conversely, flexible OLEDs are often described as "unbreakable" in terms of the panel itself. While the cover glass on top of a phone may still crack, the underlying polyimide display panel can absorb shock without shattering. This makes flexible OLEDs superior for automotive and ruggedized industrial applications.

Thickness and Weight

For modern portable devices, every millimeter counts. Rigid OLEDs typically require two layers of glass (substrate and encapsulation), usually totaling around 0.5mm to 0.7mm in thickness. Flexible OLEDs, utilizing TFE and a thin plastic film, can achieve thicknesses as low as 0.1mm to 0.2mm. This reduction allows product designers to insert larger batteries or slim down the device profile.

4. Design Freedom: Beyond Just "Folding"

A common misconception is that flexible OLEDs are only for foldable phones. While they do enable folding devices, their application is much broader.

-

Chip on Plastic (COP): In rigid OLEDs, the driver chip is bonded to the glass (Chip on Glass, or COG), requiring a bottom bezel to house the connection. In flexible OLEDs, the plastic substrate can be bent backwards behind the display. This technique, known as Chip on Plastic (COP), allows for virtually bezel-less designs where the screen extends to the very bottom edge of the device.

-

Curved Surfaces: Flexible OLEDs allow for permanently curved displays, such as the "waterfall" edges on smartphones or concave dashboard displays in modern electric vehicles.

5. Technical Specification Comparison

The following table summarizes the key technical differences between the two technologies.

| Feature | Rigid OLED | Flexible OLED |

| Substrate Material | Glass | Polyimide (PI) |

| Encapsulation Tech | Glass Frit / Metal Can | Thin-Film Encapsulation (TFE) |

| Panel Thickness | Thicker (>0.5mm) | Ultra-thin (<0.2mm) |

| Weight | Heavy | Lightweight |

| Impact Durability | Brittle (Prone to shattering) | High (Shock-resistant) |

| Form Factor | 2D Flat Only | Curved, Foldable, Rollable |

| Driver Bonding | COG (Chip on Glass) | COP (Chip on Plastic) |

| Cost | Low to Medium | High |

6. Cost Implications and Market Application

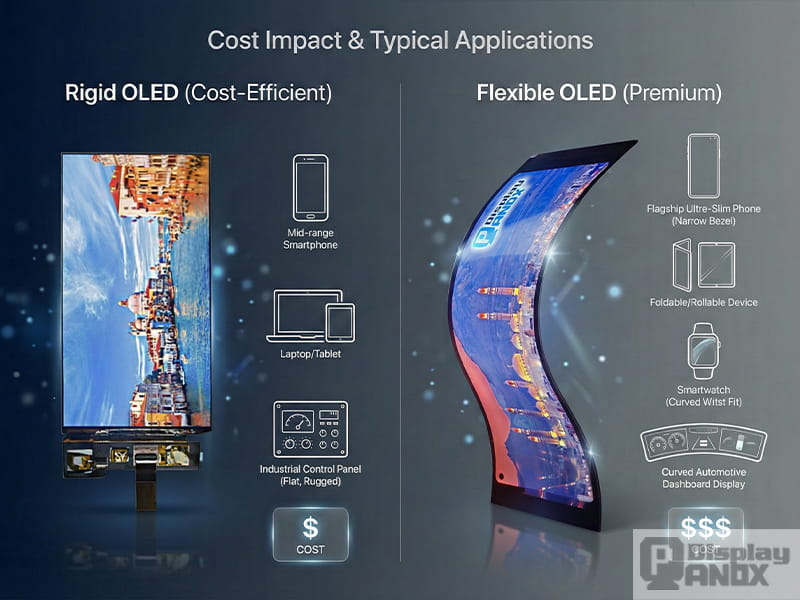

Cost Impact & Typical Applications: Rigid OLED vs Flexible OLED

Due to the complexity of the TFE and LLO processes, flexible OLED panels are significantly more expensive to produce than rigid ones. This price gap dictates their market segmentation.

Rigid OLEDs are the preferred choice for:

-

Mid-range smartphones where cost efficiency is paramount.

-

Standard laptop monitors and tablets.

-

Industrial control panels where flexibility is not required.

Flexible OLEDs are essential for:

-

Premium flagship smartphones requiring ultra-slim profiles and narrow bezels.

-

Foldable and rollable consumer electronics.

-

Wearable devices (smartwatches) that must conform to the wrist.

-

Next-generation automotive displays requiring curved integration.

Learn more: The Era of the Flexible OLED Display: How Bending Screens Are Reshaping Technology

Conclusion

Understanding the difference between rigid and flexible OLEDs is crucial for optimizing product design and budget. Rigid OLEDs offer the visual brilliance of organic self-emission at a competitive price point, making them ideal for standard flat applications. However, for designs that demand durability, ultra-thin profiles, or innovative form factors like narrow bezels and curves, flexible OLED technology is the indispensable premium solution.

As manufacturing yields for Thin-Film Encapsulation improve, the cost gap will likely narrow, eventually making flexible OLED technology the standard for a wider range of consumer and industrial electronics.

Explore our flexible OLED options for ultra-thin, curved, and foldable designs.

|