AI smart glasses, lightweight AR, and mixed reality headsets are finally moving from demos to real products. But here’s the uncomfortable truth: your “XR experience” is often decided by one thing—the microdisplay and the optics sitting in front of it.

Today’s near-eye display stack is mostly a choice between Micro LED and Micro OLED (OLEDoS). LCoS still exists in the market, but for many consumer-leaning designs it comes with tradeoffs around optical architecture, system complexity, and power that make it less likely to be the long-term mainstream path for all-day wearable devices. This article focuses on the real decision engineers keep making right now: micro led vs oled, and more specifically Micro LED vs Micro OLED.

Related: AI Glasses Display Solutions: Micro OLED、Micro LED

1) “Brightness” Isn’t Just Nits — It’s Nits at the Eye

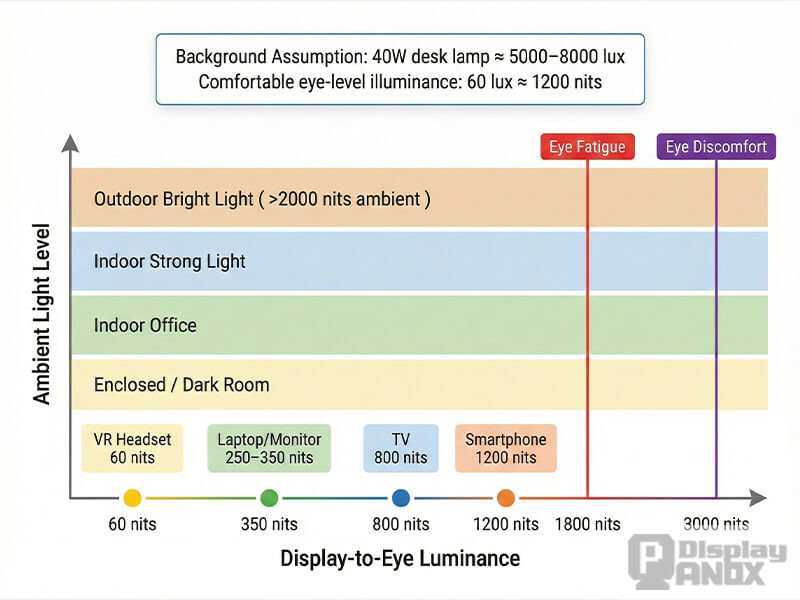

Human eye requirements for display brightness of electronic devices in different environments

Human eye requirements for display brightness of electronic devices in different environments

In XR, what matters is in-eye luminance (how bright the image looks after it passes through optics), not the panel’s raw brightness.

A simple way to think about it:

In-eye brightness ≈ Microdisplay brightness × Optical efficiency

And optical efficiency can be brutally low, because pancake lenses, beam splitters, polarizers, and waveguides all eat light.

· Pancake optics are commonly discussed around ~10% efficiency in practice (varies by design).

· Birdbath combiners are often cited around ~10–15% “display nits to eye nits” depending on implementation.

· Diffractive waveguides are typically the toughest on brightness and are frequently described as the least efficient class among mainstream AR combiners.

That’s why you’ll see a “weird” spec split in product requirements:

· Indoor clarity can be achieved with relatively modest in-eye brightness.

· Outdoor readability can demand multiples more, because ambient light competes with your image.

This is the heart of the technology debate: when optics are inefficient, the display must be a tiny sun.

Related: High-luminance display panel

2) Micro LED vs OLED vs Micro OLED — Quick Definitions (Because People Mix These Up)

OLED (traditional): emissive display used in phones/TVs (glass or flexible substrates), large-area manufacturing.

Micro OLED / OLEDoS (OLED-on-Silicon): OLED deposited on a silicon backplane, enabling extremely small pixels and very high PPI. It’s the workhorse for compact, high-resolution near-eye displays.

Micro LED microdisplay: microscopic LEDs as pixels. In microdisplay form (not TV walls), it can deliver extreme brightness—especially in monochrome or limited-color designs—making it attractive for high-brightness AR use cases.

So when someone says “OLED is too big,” they often mean traditional OLED panels. And when they say “OLED can’t do XR,” they’re usually forgetting Micro OLED exists.

3) Why Micro LED Looks Like the “Final Boss” (and Why It’s Not the Default Yet)

Micro LED microdisplays have real advantages:

· Insane brightness headroom (especially in monochrome): millions of nits are achievable in some microdisplay products.

· Long lifetime and strong thermal robustness (design-dependent).

· High potential for outdoor AR where waveguide efficiency is low and you still want a readable image.

But here’s the friction point: full-color Micro LED at high resolution and consumer cost is hard.

Full-color approaches typically involve one of these paths:

· RGB emitters with alignment / transfer challenges (yield and uniformity become painful)

· Color conversion (e.g., quantum dots) with efficiency and stability considerations

· Stacked or monolithic approaches that still face manufacturing maturity hurdles

That’s why the market often sees Micro LED microdisplays used first where the system can tolerate compromises:

· monochrome or limited color

· simpler resolution targets

· specialized optics or professional applications

To put a real-world marker on “how bright Micro LED can be,” JBD’s 0.13" MicroLED microdisplay family publicly highlights luminance up to 10 million nits (green) for AR-style use cases.

That number is exactly why Micro LED stays in every roadmap slide.

4) Why Micro OLED Is the Practical Winner for High-Quality XR Today

For most VR/MR headsets and many AR designs that prioritize image fidelity, Micro OLED wins because it’s strong where XR users actually complain:

High resolution in a tiny package

Micro OLED’s silicon backplane enables high pixel density and crisp UI/typography—critical for near-eye comfort and perceived sharpness.

Contrast and blacks that “feel expensive”

OLED’s emissive nature delivers deep blacks and high contrast, which is especially valuable for immersive content and mixed reality blending.

A clearer manufacturing direction: from color filters to “Real RGB”

A key trend is moving beyond white OLED + color filter designs (which lose a lot of light) toward RGB OLEDoS / direct emission approaches that improve optical efficiency and brightness potential. Reviews of OLEDoS development highlight how architecture choices (including tandem structures and direct emission designs) push brightness upward.

Samsung Display has also publicly positioned its OLEDoS roadmap: White OLEDoS is already in mass production, while RGB OLEDoS is scheduled for full-scale mass production starting “next year” (relative to their June 2025 release).

About “burn-in” (the honest version)

OLED technologies can exhibit image retention/burn-in under certain conditions. The practical mitigation in XR is a mix of:

· UI design (avoid static high-contrast HUDs at peak brightness)

· pixel shifting / compensation

· brightness management

· improved materials and stack design

So the right claim isn’t “it can’t happen,” but rather: Micro OLED is widely used in XR because the industry knows how to manage lifetime in real products—while still delivering top-tier image quality.

Learn more: Samsung OLEDoS Mass Production Powers Galaxy XR as Baidu, Alibaba and WiMi Hologram Move Early on AI and AR

5) Matching Display Tech to Optics: A Practical Map

Below is a simple way to align your optics choice with the display decision.

|

|---|

The key takeaway: Micro LED’s brightness advantage matters most when optics are starving the image.

If your optics are less punishing (or your use case is indoor/media/MR), Micro OLED becomes the obvious value-performance choice.

6) The 2026 Reality Check: Where the Industry Is Actually Placing Bets

If you want a “vibe check” beyond specs, follow the money:

· Apple reportedly canceled its Micro LED Apple Watch display effort in early 2024—an event widely discussed as a signal of Micro LED’s cost/scale difficulty for certain consumer products.

· Samsung Display has been actively showcasing OLEDoS progress, and industry reporting has discussed Samsung moving toward mass production of OLEDoS panels for XR hardware.

This doesn’t mean Micro LED “loses.” It means: for near-eye consumer XR, Micro OLED is the most manufacturable path to high-resolution, high-quality visuals at scalable cost today.

7) What to Look for When Buying a Micro OLED Microdisplay (Engineer-Friendly Checklist)

If you’re sourcing Micro OLED modules for AI glasses, AR viewers, or MR headsets, these are the specs that actually move your product forward:

1.Size & Resolution Fit

Your optics and eyebox goals will dictate diagonal size and resolution target—don’t pick a display in isolation.

2.Brightness (and how it’s specified)

Ask for brightness conditions (APL, duty cycle, temperature) and match it to your optics’ real transmission.

3.Color & Pixel Architecture

If you care about efficiency and brightness, understand whether the design is closer to color-filter approaches or RGB-oriented architectures.

4.Interface & Integration

Common integration paths include MIPI-style interfaces and controller-board solutions depending on your system architecture (prototype vs product).

5.Power & Thermal Plan

Near-eye devices are wearable thermal systems. Budget power early and validate heat paths.

8) Why Micro OLED Is the Best “Application-Ready” Choice for Most XR Products

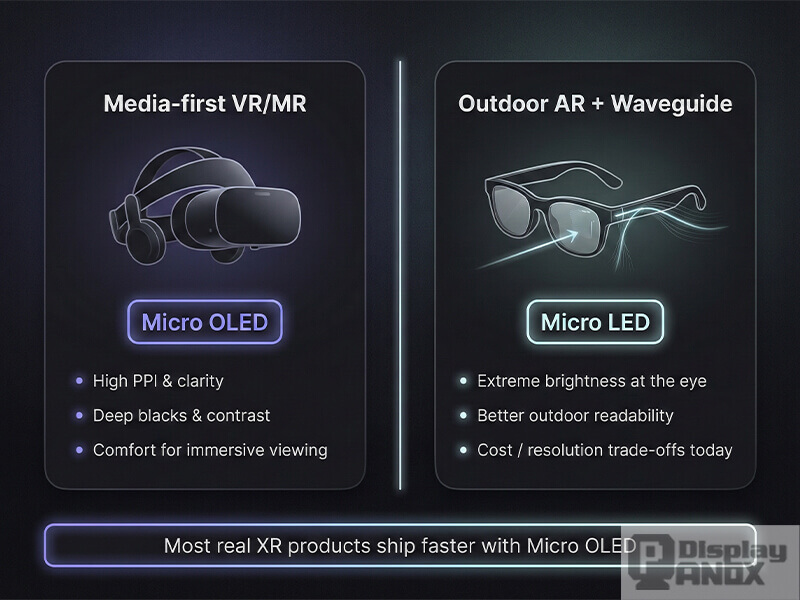

Micro OLED vs Micro LED: A Practical XR Decision Map

So, in the micro led vs oled debate, here’s the practical answer:

· If your product is media-first VR/MR, prioritizing resolution, contrast, and comfort → Micro OLED is the most application-ready choice.

· If your product is outdoor AR with ultra-thin waveguides and you need extreme brightness at the eye → Micro LED becomes compelling, especially where the system can accept today’s cost/resolution constraints.

For most teams trying to ship a real XR product (not a lab demo), Micro OLED is the fastest path to a premium visual experience with a supply chain that’s actively scaling.

Ready to Build? Choose Micro OLED That Matches Your Optics and Use Case

If you’re developing AI glasses, AR viewers, or MR headsets and want a microdisplay that balances image quality, integration feasibility, and a realistic path to production, Micro OLED is the sweet spot.

Browse our Micro OLED microdisplay options for near-eye applications, and if you already know your optics type (pancake / birdbath / waveguide), share it with us—we can help you shortlist the right resolution/brightness class for your target in-eye luminance.

Learn more: LCD vs LED vs OLED vs Micro LED vs Micro OLED