Micro OLED Display

What is micro OLED ?

Micro OLED (OLEDoS) displays are silicon-based OLED display that use a monocrystalline silicon wafer as the actively driven backplane, so it is easier to achieve high PPI (pixel density), a high degree of integration, and small size. This ensures they are easy to carry, have good anti-seismic performance, and have ultra-low power consumption.

-

Size(inch)

- 0.39~1.0

- 1.0~1.9

- 2.0~2.9

- 3.0~3.9

- 4.0~4.9

- 5.0~5.9

- 6.0~6.9

- 7.0~7.9

- 8.0~9.9

- 10~20

-

Interface

- I2C

- SPI

- Parallal

- MCU

- CPU

- RGB

- MIPI

- LVDS

- eDP

- HDMI

-

Display Color

- Monochrome

- Double Color

- Full Color

-

Orientation

- Landscape

- Portrait

| Model | Size | Display Type | Resolution | Interface | Display Brand | Image | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.39 inch micro OLED For AR

|

0.39 | Micro OLED | 1024x768 | I2C,RGB | PanoxDisplay |

|

||||||||||

0.39 inch Micro OLED For AR Type-c Board

|

0.39 | Micro OLED | 1920x1080 | MIPI | BOE |

|

||||||||||

0.47 inch Micro LCD LCOS Display For AR

|

0.47 | Micro LCD | 800(RGB)×600 [SVGA] | LVDS | Epson |

|

||||||||||

/049microOLEDico.jpg)

0.49 inch Micro OLED Display 1920X1080 MIPI Interface

|

0.49 | Si-OLED, OLED | 1920(RGB)×1080, FHD 4391PPI | SPI,MIPI | BOE |

/049microOLEDico.jpg)

|

||||||||||

0.5 inch 1600x1200 Micro OLED 1000 cd luminance 120 Hz

|

0.5 | Micro OLED | 1600x1200 | I2C,MIPI | Panox Display |

|

||||||||||

0.5 inch micro OLED For AR

|

0.5 | Micro OLED | 1024x768 | LVDS | Sony |

|

||||||||||

0.68 inch Micro OLED 5000 Brightness Fast Response

|

0.68 inch | Micro OLED | 1920 × 1200 (WUXGA) | SPI,LVDS | Sony |

|

||||||||||

0.71 inch Micro OLED FHD For AR

|

0.71 | Micro OLED | 1920x1080 | LVDS | Sony |

|

||||||||||

0.71 inch Micro OLED For AR

|

0.71 | Micro OLED | 1920x1080 | I2C,MIPI | BOE |

|

||||||||||

0.71 inch Micro OLED 1920x1080 LVDS 3000 nits

|

0.71 | Silicone based Micro OLED | 1920(RGB)×1080, FHD 3078 PPI | LVDS | Sony |

|

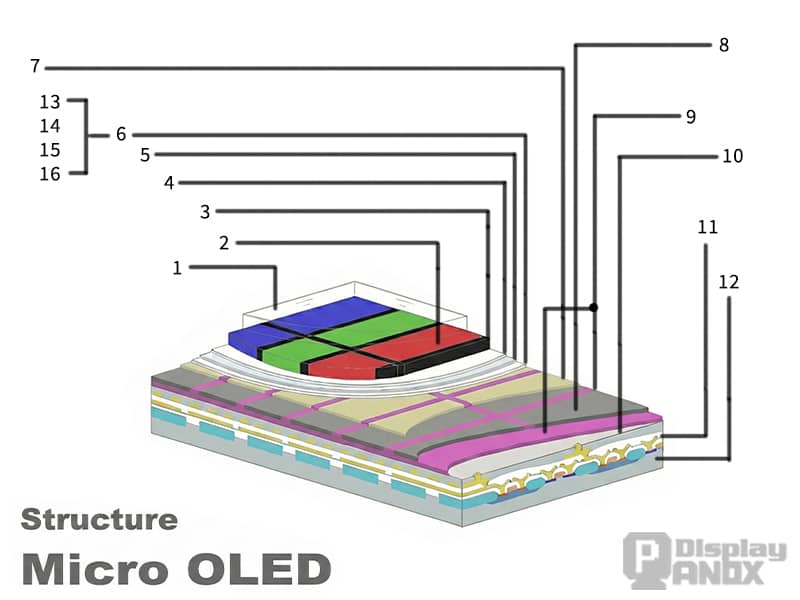

Structure of Micro OLED

1. Cover Glass 2. RGB Color Fillter 3. Black Material Matrix Isolation 4. Polymer and Ceramic Film Encapsulation 5. Transparent Common Cathode(Upper Electrode) 6. Organic Ligh-Emitting 7. Pixel Anode Dielectric(lowe electrode) 8. Pixel Graphics Conductive 9. Pixel Isolation 10. SIO2 11. CMOS Driver Circuit 12. Monocrystalline Silicon Substrate 13. Hole Injection/Transport 14. WOlED Light Emitting 15. Electron Injection/Transport 16. Cathode Buffer

On the backside of Micro OLED (OLEDoS), it has an integrated CMOS driver circuit on the semiconductor, so it won't need an extra driver IC like LCD or OLED. Then it`s pixel pattern conducting layer above the CMOS circuit.

The other layers are just like OLED, from bottom to top, there are a lower electrode, an isolation layer, an organic light-emitting layer, and an upper electrode (for connecting cathodes of all pixels).

In a word, the white light and color filter layer is to generate FULL-COLOR images. The color filter layer is comprised of an RGB color filter and a black material matrix isolation strip.

The last step is to use a closed glass cover for encapsulation, the a complete silicon-based OLED display comes out.

Manufacturers of Micro OLED

The main Micro OLED manufacturers are Sony, BOE, Epson, Olightek, and Sidtech. At present, they are mainly used in immersive and penetrating applications such as AR and VR devices, telescopes, microscopes, and gunsights. Panox Display has built reliable access to micro OLED manufacturers. We promise every micro Displays on sell are all original A grade products.

More About Micro OLED (OLEDoS)

Customized Service

It`s just a beginning to get display panels from us, then clients need to solve cover glass/touch panel, driving board, connectors on PCB.Fortunately Panox Display provide complete display solutions.

Connectors

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Cover Glass/Touch Panels

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

Controller/Driver Boards

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

If our display fit your application, subscrlbe for monthly Insights

If it`s urgent, try to contact

Whatsapp: +86 18665870665

Skype: panoxwesley

QQ: 407417798